In the highly competitive metal fabrication market, core challenges such as inconsistent cutting precision, slow changeovers for complex parts, and low efficiency due to excessive manual intervention are hindering business growth. Simply extending working hours or adding manpower is no longer a viable solution. Upgrading equipment to fundamentally boost productivity has become an imperative. This article provides an in-depth analysis, using Hymson's fiber laser cutting machines as an example, to explore how systematic upgrades in hardware, software, and processes can lead to a quantum leap in both precision and efficiency.

A Framework for Measuring the Value of an Equipment Upgrade

Evaluating the value of an equipment upgrade requires more than just looking at the purchase price. A multi-dimensional framework should be established:

Four Core Metrics:

- Precision: Directly determines product quality and acceptance rates.

- Efficiency: Affects order delivery cycles and output per unit of time.

- Yield: The direct result of high precision and stability, reducing scrap.

- Material Utilization: Intelligent nesting and precise cutting minimize sheet metal waste.

- Return on Investment (ROI): Calculated by (Increased Output Value + Savings in Material/Labor Costs) / Equipment Investment to forecast the payback period.

- Hidden Costs: Frequent downtime for repairs, high energy consumption of old equipment, and rework caused by insufficient precision are all hidden costs that must be factored in.

Key Hardware Influencing Laser Cutting Precision and Efficiency

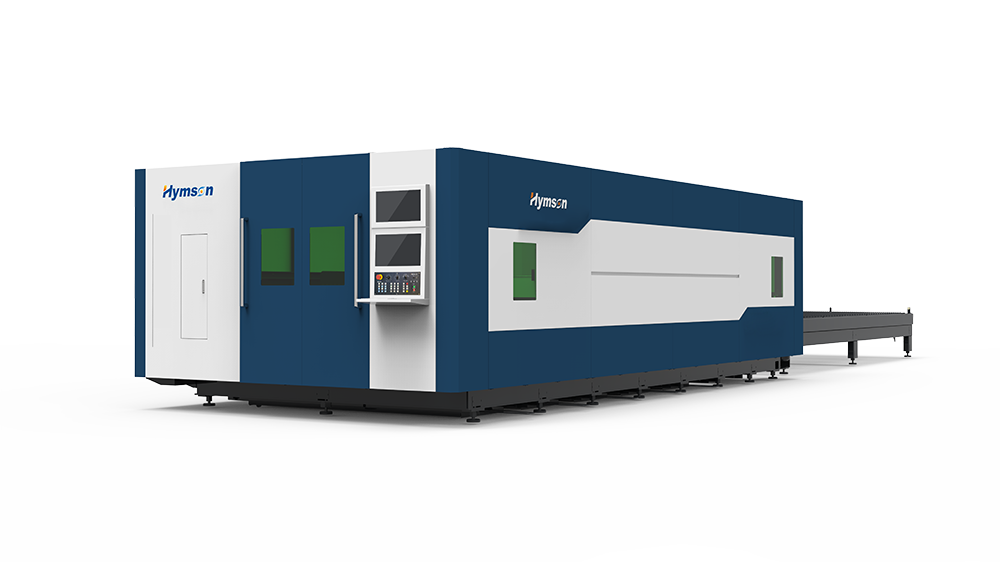

Hardware is the foundation of performance. An exceptional laser cutting machine derives its high precision and efficiency from the seamless integration of key components.

- High-Rigidity Machine Bed: Hymson's models feature an upgraded mortise-and-tenon joint welded machine bed, which undergoes high-temperature annealing to eliminate welding stress. This design ensures the machine's long-term strength, high precision, and durability, providing a stable platform for micron-level accuracy.

- Lightweight, High-Strength Gantry: A patented drawn aluminum gantry design offers low mass, high tensile strength, and superior dynamic performance. This allows the X/Y axes to achieve a maximum acceleration of up to 1.5g and a maximum speed of 169 m/min (data from select mid-format models), significantly reducing non-cutting travel time.

- Active Thermal Compensation Technology: This is a core technology for maintaining long-term stability. It effectively compensates for the impact of thermal deformation on the parallelism of reference guides during prolonged operation, ensuring consistent cutting accuracy and achieving an X/Y axis positioning accuracy of ±0.03 mm/m and a repeatability of ±0.02 mm/m.

- Brand-Name Servo Motors: High-resolution encoders paired with brand-name servo motors and drives are essential for guaranteeing fast response and precise positioning.

Synergistic Upgrades in Software and Processes

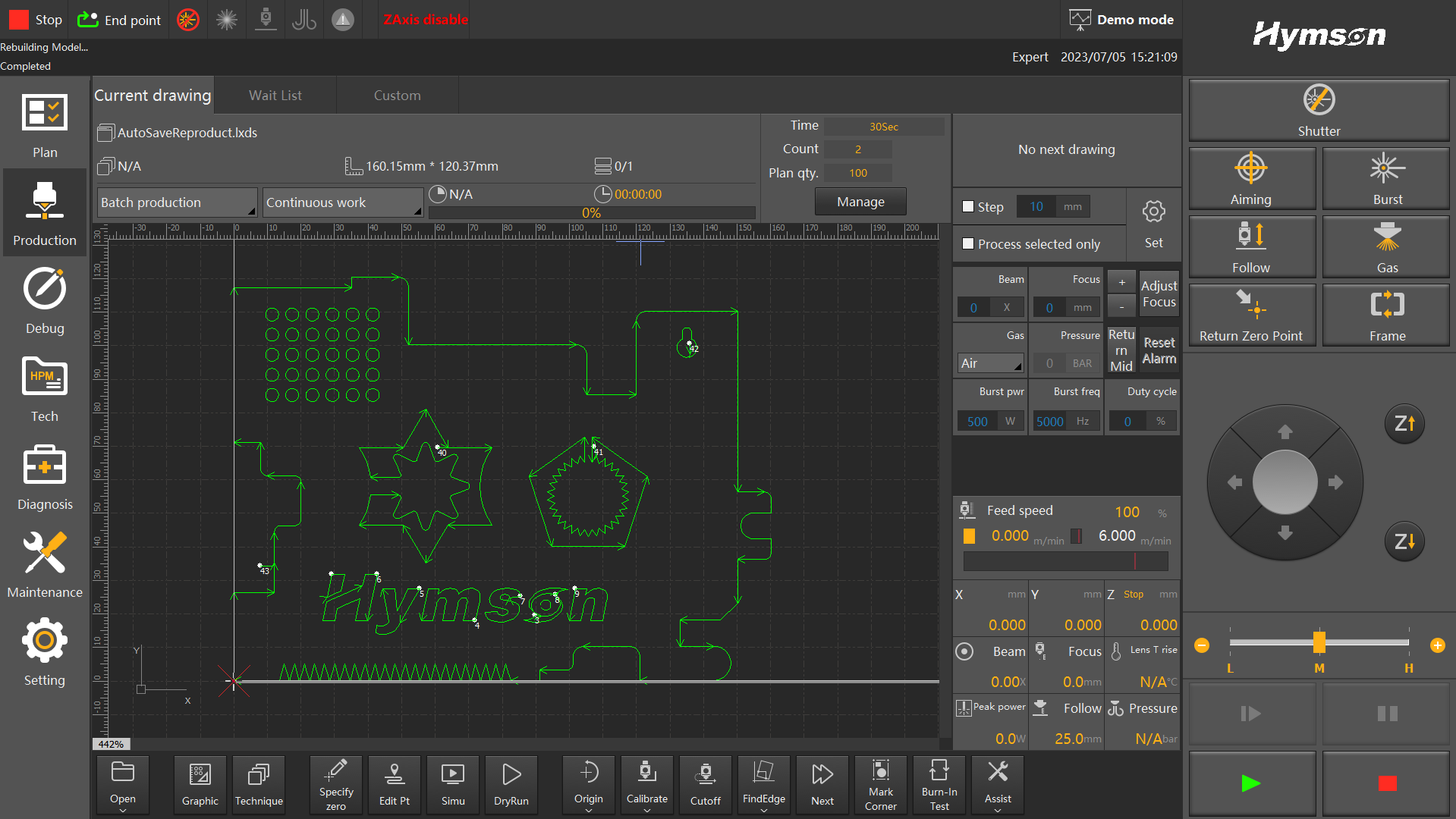

If hardware is the body, software is the brain. An advanced CNC system is key to unlocking the full potential of the hardware.

- Advanced Control System: The FSCUT control system featured in these advanced machines, based on a Windows 10 architecture and an EtherCAT bus control platform, has a response time of ≤100us. It is more than just an interface; it's a "super brain" integrating production management, process handling, intelligent assistance, and modular diagnostics.

- Interfaces for Automation: The system can seamlessly connect with automated loading/unloading systems, smart warehouses, and other automated production lines, paving the way for manufacturers to transition from standalone smart machines to fully automated "lights-out factories."

Ensuring Quality and Stability

- Zoned Ventilation System: This system uses intelligent, segmented fume extraction with follow-the-head control. Valves in a specific zone open only when the cutting head is operating in that area, resulting in more efficient dust removal with a shorter path and concentrated airflow. This protects both the working environment and optical components like lenses.

- Preventive Maintenance: Advanced equipment often includes self-diagnostic functions, such as the modular diagnostics and maintenance in the FSCUT system. This helps users quickly identify issues, and when combined with routine optical path checks and cooling system maintenance, it minimizes unplanned downtime.

Success Story: The Leap from Traditional to Smart Manufacturing

Background:

A precision sheet metal fabrication company was struggling with aging equipment, with accuracy degrading to ±0.1mm and slow speeds, making it difficult to meet the precision and delivery demands of high-end clients.

- Upgrade: They introduced one of Hymson's new-generation high-power laser cutting machines.

- Data Comparison:

- Precision: Positioning accuracy improved from ±0.1mm to ±0.03 mm/m, with repeatability reaching ±0.02 mm/m. The first-pass yield of products increased by 30%.

- Efficiency: Maximum positioning speed increased from 60 m/min to 169 m/min, and maximum acceleration rose to 1.5g, resulting in an overall processing efficiency boost of over 30%.

- Automation: By connecting a simple loading/unloading unit via the advanced control system, they achieved continuous production, reducing material handling wait times by 55%.

Common Pitfalls and Risk Mitigation

- The "Power-Only" Fallacy: High power does not automatically equal high efficiency and precision. The machine's dynamic performance and the control system's response speed are equally critical.

- Overlooking Software: Ignoring the ease of use, compatibility, and intelligence of the control system can prevent the equipment's full potential from being realized.

- Lack of Holistic Planning: Failing to consider workshop layout (e.g., a large-format machine can occupy a 20m x 7m footprint) and the automation upgrade path can lead to costly secondary modifications.

Supplier Evaluation Checklist

- Technical Strength: Do they possess core technologies like active thermal compensation and patented gantry structures?

- Product Line Completeness: Can they offer a full range of solutions, from 3m to 8m tables and from 3kW to 80kW power?

- Service and Support: Do they have a responsive local service network and remote diagnostic capabilities?

- R&D and Iteration: Is the supplier continuously investing in R&D, ensuring your equipment has an upgrade path in the future?

Conclusion Upgrading laser cutting equipment is a systematic project that requires a comprehensive assessment of everything from hardware rigidity and dynamics to software intelligence and openness, as well as continuous process optimization. Choosing equipment, like the advanced machines offered by Hymson, that integrates high precision, high efficiency, and automation from the design stage is a wise move for manufacturing enterprises to stand out and achieve sustainable growth in a competitive market.

Share This Post: