Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. In this article, we will walk through the basics of fiber laser cutting machines.

How does a cnc laser metal cutting machine work?

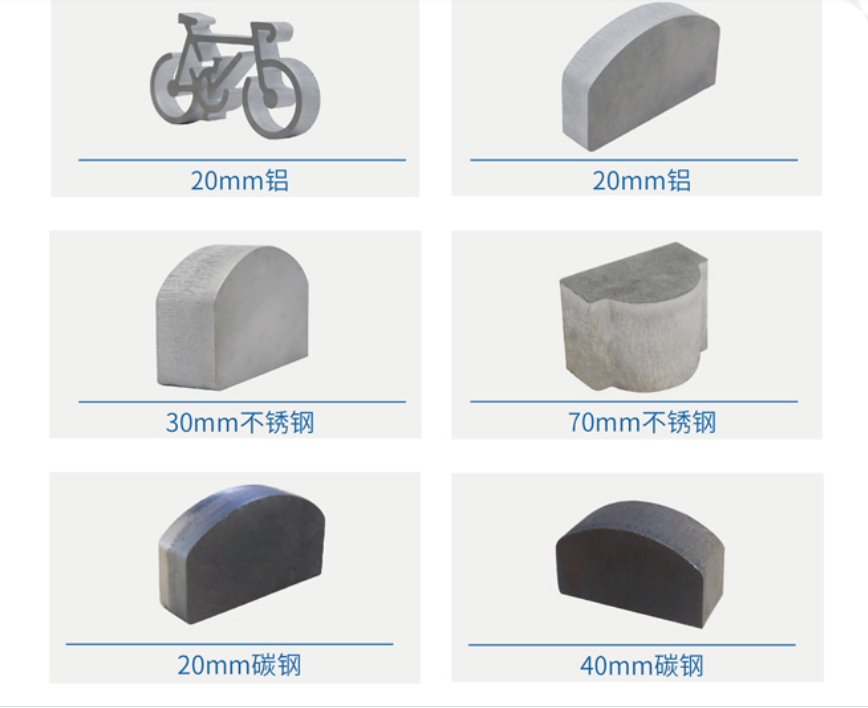

A metal cutting laser cutter uses a fiber laser generator as the light source to cut materials. It output a high energy density laser beam, and is gathered on the surface of the workpiece, melting and gasifying the area that is irradiated by ultrafine focus spectrum, and moving spot illumination through a CNC mechanical system.

With the relative position of the beam and the workpiece moving, the material is eventually cut to form a slit, thus achieving the purpose of cutting. The fiber cutting machine is more and more popular among domestic and foreign users due to its high level of automatic cutting, flexibility, high processing efficiency, high precision and short product cycle.

Application of CNC metal sheet cutting machine

1. Decoration industry

Thanks to the high speed and flexible cutting of the cnc fibre laser cutting machine.

, many complex graphics can be quickly processed by efficient fiber laser cutting system and the cutting results have won the favor of decoration companies. When customers order a special design, the relevant materials can be directly cut out after the CAD drawing is made, hence there is no problem in customization.

2. Automobile industry

Many metal parts of the automobile, such as car doors, automobile exhaust pipes, brakes, etc. can be processed precisely by automatic metal cutting machine. Compared with traditional metal cutting methods like plasma cutting, fiber laser cutting ensures wonderful precision and work efficiency, which highly improves the productivity and safety of automobile parts.

3. Advertising industry

Due to the large number of customization products in the advertising industry, the traditional processing method is obviously inefficient, and the metal cutting press machine is quite suitable for the industry. No matter what kind of designs, the machine can produce high quality laser cut metal products for advertisement use.

4. Kitchenware industry

Nowadays people have higher demand on the design and application of kitchenware, so kitchen-related products have a promising market around the world. Metal plate cutting machine is very suitable for cutting thin stainless steel with fast speed, high precision, good effect, and smooth cutting surface, and can realize customized and personalized products development.

Conclusion

CNC metal cutting machine has an effect on every aspect of the manufacturing industry and it is useful for businesses to scale and produce more cost-effective for customers. As technology continues to change, the versions of the CNC fiber laser cutting machines will upgrade as well, which guarantees optimal performance and exhibits the highest level of accuracy and consistency. Contact us for more details about Hymson cnc laser cutting machine sheet metal with low sheet metal laser cutter price.

Share This Post: