Hymson is Fiber laser metal cutting machine manufacturer in china that is operating to bring forth a superior range of industrial machinery and equipment. Based in China (Jiangmen), fiber laser cutting machine factory Hymson is recognized as a reliable manufacturer, exporter, and supplier of different kinds of industrial equipment like engraving and cutting machine, fiber laser cutting machine for metal sheet, laser chiller, laser cutting machine, laser marking machine, mirror lens, CO2 laser power supply, metal, brass, wood engraving machine, power supply unit, laser machine air compressor, medium pressure centrifugal blower, focus lens, and Co2 laser tube. include diffrent power type:1.5 kw fiber laser cutting machine , 2000w laser cutting machine, 3kw fiber laser cutting machine, 4kw fiber laser cutting machine, 6kw fiber laser cutting machine.

Laser Power of the Fiber Laser CNC Machine

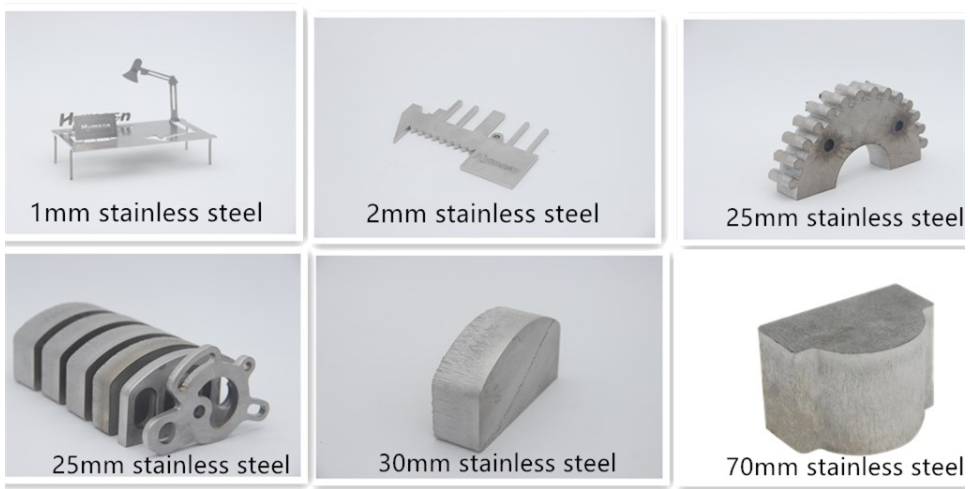

As High power laser cutting machine continue to go deep into the market, more and more high-power cnc laser steel cutting machine have been developed. Its power ranges from a few hundred watts to tens of thousands of watts. The maximum thickness of the cut metal will also vary depending on the laser power. The price differs depending on a different power. Hymson laser has a 1000w laser cutter, 1.5 kw fiber laser cutting machine,2kw laser cutting machine, 3kw laser cutting machine, 4kw fiber laser cutting machine, and other more powerful fiber laser processing machines to choose from. Laser power plays an important role in cutting efficiency and the price. Find machines with different fiber powers and cutting thicknesses.

stainless steel laser cutting machine price

High-Speed Cutting for Easy and Efficient Operating

The fast cutting speed is a valid solution for increasing the integrity and efficiency of the complicated workpiece without any heat influence. This makes the CNC fiber laser cutting machines ideal for fabricating some complex and refined products. Moreover, you can plan the cutting path and optimizes the turning and the addition and subtraction process as well as the interpolation.

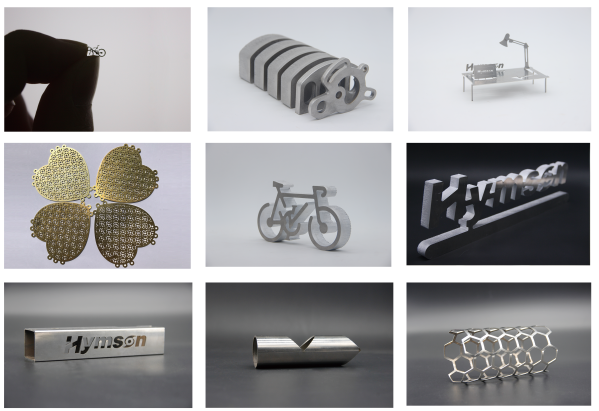

Cut by cnc laser pipe cutting machine or cnc metal sheet cutting machine

Cutting Technology of Laser Cutter

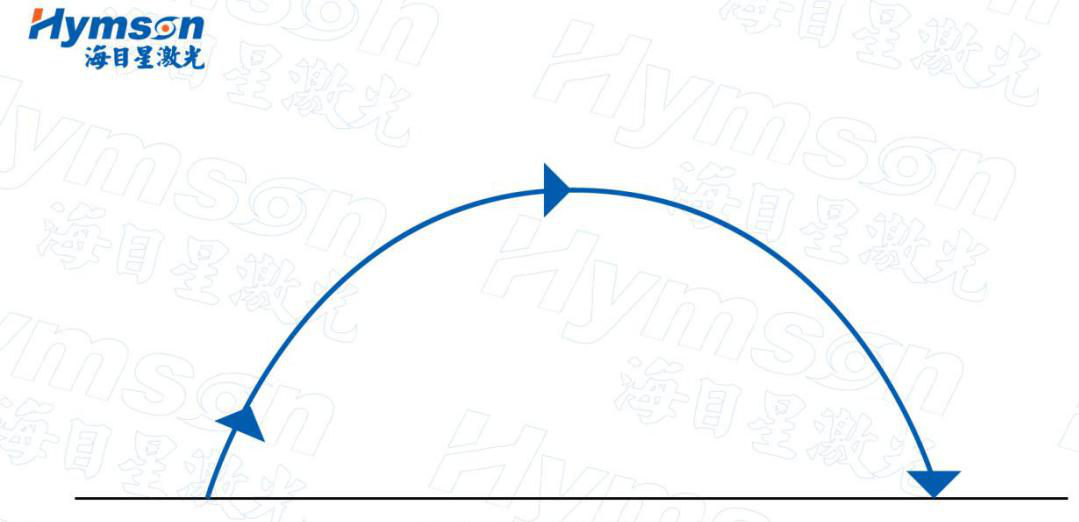

1. Leapfrog Cutting

● The new leapfrog function based on CNC eliminates the disadvantage of “rectangular” motion or false leapfrog of the cutting head.

● Adopting the motion of a parabola, with jumping and falling based on CNC to achieve real-time control and with accurate and rapid positioning, thus significantly improves the efficiency of processing.

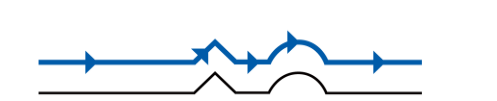

2. Automatic Obstacle Avoidance

● When a workpiece cocks, the cutting head can identify it automatically and rise rapidly to avoid the obstacle and locate the position of the next workpiece intelligently

● To reduce the probability of collision between the cutting head and the workpiece; ② to guarantee the consistency of cutting during processing, thus improves the efficiency of processing; ③ to locate the position of the next workpiece intelligently, thus reduces the probability of integral transfer of a sheet and reduces the waste of sheets; ④ to reduce the workload of the operator and editor through the simple and intelligent operation.

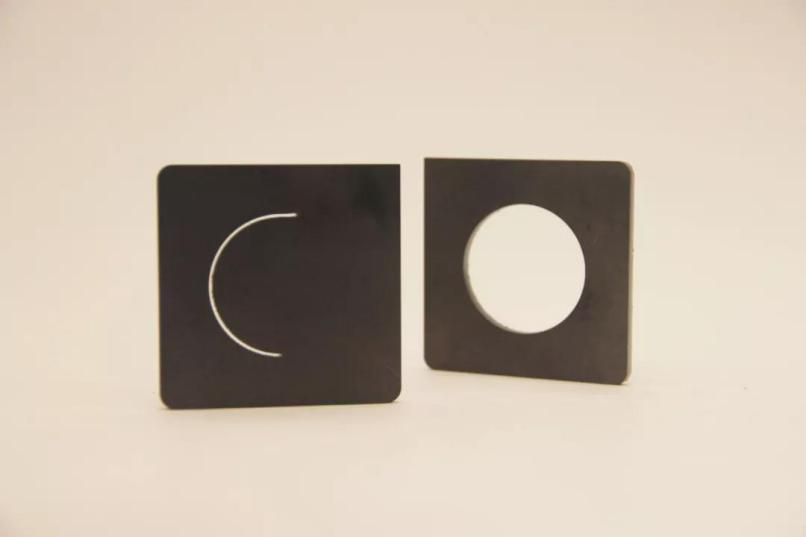

3. Aluminum Alloy Burr-free Cutting (Optional)

● Burrs are easy to appear in aluminum alloy cutting, so additional manual or mechanical polishing is needed, which increases product production processes, thus reduces the productivity, extends the shipment cycle, and increases the production cost.

● Hymson’s “Aluminum Alloy Burr-free Cutting” process realizes no burrs, no wrinkles, high precision, no mold consumption, no need for repairing molds, saving of time of mold replacement, saving of processing fee, reduction of product cost, etc.

4. Rapid Perforation

Hymson’s characteristic new technology, which reduces the time of perforation and optimizes the whole process of perforation to achieve stable, fast, high quality perforation

● High Speed: To penetrate various sheets of medium thickness consistently and quickly within 200ms

● High Efficiency: To save time by over 80% as compared to the time of general perforation of 1-2 seconds

● High Quality: The perforation process is stable, without blasting. The technology is safe and efficient.

● Easy to Operate: Simple and intelligent, reducing the workload of the operator and edito.

5.Arbitrary Point Cut-in

● During the real production, when a part of the sheet is not cut thoroughly due to dust on a certain node on the sheet, insufficient gas, etc., the solution for general laser cutting machine manufacturers is resetting the system interface, that is, going through the process again from the start to the end of the procedure operation which is time-consuming, consuming a lot of materials, and high-cost.

● With Hymson’s “Arbitrary Point Cut-in” function, the cutting head can cut in at arbitrary point, without cutting from the start to the end, thus solves the problems of time-consuming, consumption of a lot of materials, high cost, etc.

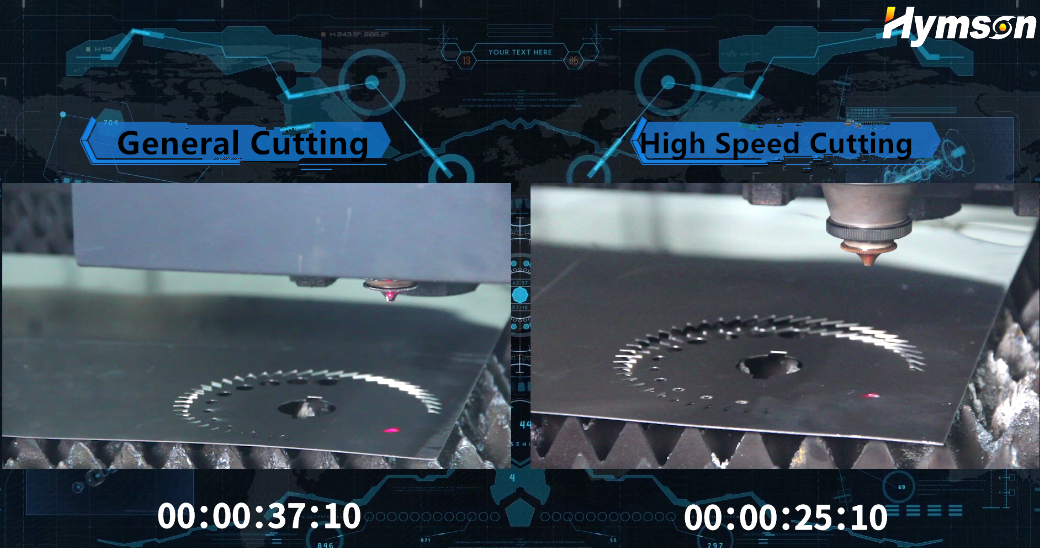

6. High Speed Cutting

● General rapid acceleration and deceleration, such as violent impact vibration, toothed rack break-off, etc., may damage the hardware of the lathe.

● Hymson’s “High Speed Cutting” function plans the cutting path in advance and optimizes the turning and the addition and subtraction process as well as the interpolation.

● Efficient: Significantly improving the acceleration and deceleration and reducing the time of acceleration and deceleration; increasing the efficiency of complicated workpiece processing by 30%

● Safe: Absorbing the shocks from acceleration and deceleration in cutting on the lathe to guarantee high speed processing of the machine and to protect the lathe against shocks

Hymson Laser has been paying attention to the fiber laser sheet metal application market, and established the sheet metal intelligent equipment division. After years of research and development, Hymson Laser has accumulated solid laser cutting technology and has mature automated manufacturing experience. And for sheet metal applications in different industries, to provide users with professional and high-quality product portfolio and services,including comprehensive laser automation solutions such as laser plate cutting intelligent equipment, laser tube cutting intelligent equipment and laser automation software.

Our current customers are experienced experts in varies of industry, such as sheet metal , engineering machinery, construction, smart furniture, bathroom & kitchen hardware, electric equipment, automobile,aviation and petroleum industry.

Share This Post: