Metal tube demand is rising across industries like automotive, construction, smart furniture, and sanitary ware. But conventional cutting methods—such as mechanical saws or low-speed lasers—often fall short, leading to slow production, high tail waste, limited flexibility, and labor-heavy processes.

As manufacturers push for higher efficiency, accuracy, and cost control, outdated cutting systems could be limiting your growth.

This article examines how the Hymson G Series High-Speed Tube Laser Cutting Machine solves these problems with modern performance, automation, and precision built for real production lines.

Introducing Hymson’s G Series—A New Standard for Steel Tube Cutting

The Hymson G Series is a fully automated, high-speed fiber laser cutting system specifically built for metal tube applications.

It is designed to process a wide range of tube shapes—including circular, square, rectangular, oval, and custom profiles—and supports materials like carbon steel, stainless steel, aluminum, copper, and galvanized pipe.

Core system features include:

- Cutting diameter range: Ø20mm–Ø350mm

- Tube length: Up to 6,000mm

- Cutting head power options: 1kW–6kW fiber laser

- Fully automatic feeding, positioning, cutting, and unloading

- Compatible with thin-wall and heavy-wall tubes

- Integrated TubeNest nesting software and FSCUT3000 control

Whether you’re a furniture manufacturer, an automotive part supplier, or a construction steel processor, the G Series is ready to operate at industrial scale—with speed, accuracy, and flexibility.

Engineered for Output: What’s Under the G Series Hood

The G Series isn't just an upgrade in speed—it's a complete redesign of how tube cutting machines support large-scale production. Based on years of industry feedback and continuous R&D, Hymson delivered concrete improvements in five critical areas:

Performance Acceleration

- 1.5G ultra-high acceleration ensures reduced cycle time per cut

- 8 Hz low-pass filtering minimizes vibration, improving cut quality

Precision Chucks and Fixturing

- One-piece side-mounted chuck base for greater rigidity

- Dual-chuck synchronization for zero-tail cutting

- Standard roller jaws offer better grip on deformed or high-strength pipes

- 180 rpm high-speed self-rotation with a clamping force of up to 150kg

Sealed Protection and Long-Term Stability

- Fully enclosed chucks and sealed guide rails prevent dust accumulation

- Protect mechanical components from wear, jams, or corrosion

Integrated Smart Control

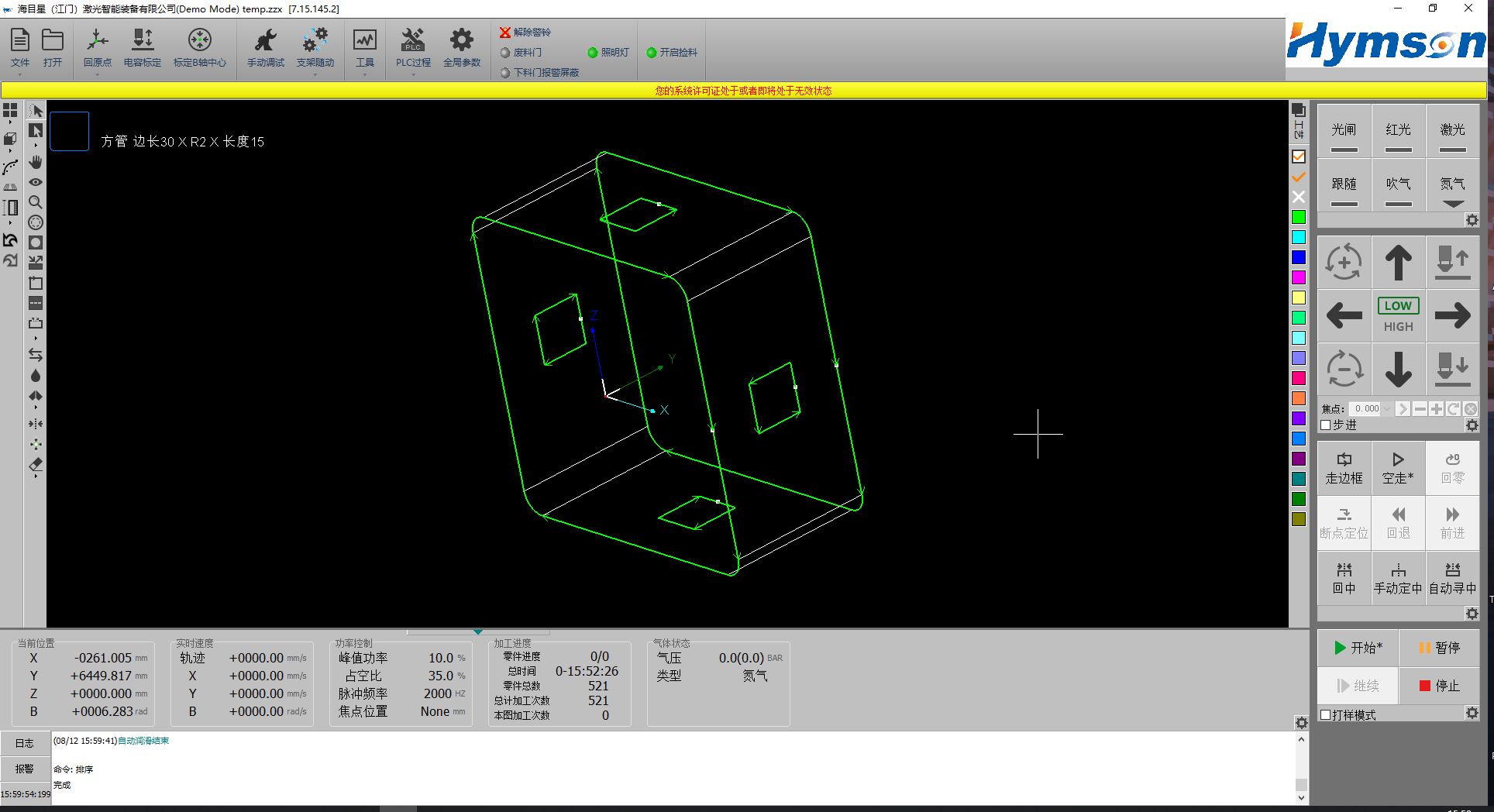

- FSCUT3000 intelligent tube-cutting control system

- TubeNest software enables complex nesting layouts with minimal scrap

- Easy-to-use interface with real-time monitoring and alerts

Robust Mechanical Structure

- Reinforced machine bed with +150% torsional rigidity

- 7 m feeding capability with a variety of pipe buffering

- Servo-driven unloading and flip-discharge for continuous operation

FSCUT3000 control system

Six Common Tube Cutting Problems—Now Solved

Below is a direct comparison of the pain points faced in traditional systems vs. the solutions offered by the Hymson G Series:

1. Inefficiency with Small to Medium Tubes

Traditional machines often vibrate when cutting small or lightweight tubes.

The G Series uses variable diameter wheel supports and automatic centering for optimal stability.

2. Slow Cutting Speeds

Legacy systems have slow acceleration, abrupt stops, and inconsistent feeding.

The G Series provides 1.5G acceleration and 180 rpm chuck spin speed—over 30% faster cycle times.

3. Material Waste Due to Long Tailing Ends

Most two-chuck mechanisms leave 30–80mm of material as “tail.”

The G Series allows offside front chuck cutting and reverse cutting to achieve zero tail.

4. Dust and Debris Reduces Precision Over Time

Unprotected guides corrode or jam in gritty shop conditions.

Fully sealed dustproof structures help maximize cutting and part consistency.

5. High Labor Dependency

Older systems require 2–3 skilled operators to manage tube shifting and alignment.

The G Series requires only one operator with fully automatic handling and position control.

6. Unreliable After-Sales Support

Low-end systems come with limited or delayed tech support.

Hymson provides comprehensive warranty coverage and a global service network.

Is It Right for Your Industry? See Who It’s Built For

The G Series is engineered to integrate into a wide variety of tube-centric manufacturing environments, including:

|

Industry Sector |

Application Examples |

|

Sheet Metal Fabrication |

Steel structural supports, square tube frames |

|

Construction Equipment |

Loader/chassis tubing, crossbars for machineries |

|

Steel Building Components |

Piping and posts for frameworks |

|

Metal & Smart Furniture |

Chairs, desks, shelving, oval and round tubes |

|

Bathroom Hardware |

Towel racks, round bars, stainless accessories |

|

Power Cabinets & HVAC |

Enclosures, support frames, pipe connectors |

|

Automotive Part Suppliers |

Body frames, exhaust crossmembers, chassis tubes |

|

Aerospace Components |

Reinforced structural tubes, mounts |

|

Oil/Gas Infrastructure |

Pipe fittings, casing tubes, auto-welded sections |

Final Thoughts

For manufacturers and equipment buyers, the cutting process is no longer just a workshop task—it’s a productivity battleground.

If your factory is:

- Processing more than 100 pipes per day

- Handling multiple material types or tube shapes

- Struggling with tail loss, inconsistent quality, or operator overload

- Planning to introduce digital control for smarter production

Then the Hymson G Series is not a luxury—it’s a logical step forward.

You get faster production, better accuracy, material savings, and a more resilient, automated operation. That’s real measurable value, every shift.

Frequently Asked Questions

Q1: What pipe shapes can the Hymson G Series handle?

Round, square, oval, D-shaped, rectangular, and custom cross-sections—with diameters from Ø20mm to Ø350mm.

Q2: What materials are supported?

Carbon steel, stainless steel, galvanized pipe, aluminum, copper alloy, and more (thin- or thick-wall supported).

Q3: Can it integrate with my smart manufacturing system?

Yes. Full compatibility with MES, ERP platforms via Ethernet/OPC communication protocols.

Q4: What's the operational training time?

Operator can be training-ready in 3–5 days thanks to intuitive controls and a guided interface.

Q5: Can I request a sample cut or book a live demo?

Yes. Contact our local distributor or fill out the demo request form on our website.

Share This Post: