In the ever-evolving manufacturing landscape, speed and precision are no longer optional—they are survival essentials. Whether you're in metal furniture production, auto parts manufacturing, or energy engineering, cutting pipes faster and more accurately translates directly into profitability. But how much faster can a high-speed tube laser cutting machine truly be? In this article, we dive deep into the Hymson G Series—designed for speed, accuracy, and scalability—to understand how it outpaces traditional cutting methods and elevates production to the next level.

What is a High-Speed Tube Laser Cutting Machine?

A high-speed tube laser cutting machine is designed specifically for rapid and precision cutting of round, square, rectangular, oval, and customized-profile tubes. These machines utilize fiber laser technology, servo-driven motors, and automated feeding systems to streamline the cutting of metal tubes with unmatched repeatability.

The Hymson G Series is one of the leading high-speed tube laser cutting systems available today. Developed by Hymson Laser—a well-established brand specializing in industrial laser and automation solutions—this machine combines cutting-edge engineering with industry-leading automation.

Key features include:

- Cutting speeds up to 100 m/min

- Positioning accuracy within ±0.03 mm

- Automatic loading and unloading system

- Self-developed control software

- Full support for multiple tube shapes and lengths (standard 6 m–12 m)

Speed Comparison: Hymson G Series vs. Traditional Cutting

Table: Speed & Efficiency Comparison

|

Feature |

Hymson G Series |

Traditional Cutting (Saw/Plasma) |

|

Max Cutting Speed |

Up to 100 m/min |

Under 15 m/min |

|

Positioning Accuracy |

±0.03 mm |

±0.5 mm |

|

Setup Time per Pipe |

< 10 seconds |

1–3 minutes |

|

Pipe Type Compatibility |

Round/Square/Oval/Customizable |

Mostly Round/Simple |

Why is the Hymson G Series So Fast?

The true power of Hymson lies beneath its hood. Here’s what makes it outperform other systems:

- Heavy-duty gantry frame structure—ensures vibration-proof cutting during high-speed operation.

- High-precision linear guide rails combined with high-response servo motors—enabling fast, stable motion.

- Strong multi-axis motion control system developed in-house for optimal cutting paths.

- Fully automatic loading and unloading system integrated for uninterrupted production.

- Intelligent clamping and positioning system—self-centers round and rectangular tubes without manual adjustments.

- Smooth material transition and nesting algorithms reduce idle time and boost efficiency.

Productivity Benefits for Manufacturers, Distributors & Agents

Whether you're a manufacturer, an agent, or a distributor, the Hymson tube laser cutting solution presents practical advantages:

For Manufacturers:

- Up to 70–80% reduction in setup/changeover time.

- Decreased labor cost with automated material feeding/unloading design.

- Compatibility with various tube lengths and shapes allows flexible production.

- Precision cutting greatly reduces defect rate and post-processing time.

For Distributors and Agents:

Strong product performance allows penetration into industries requiring fast turnaround.

Lower technical barrier with full support, training, and after-sales from Hymson.

Premium specs at competitive pricing compared to other international brands.

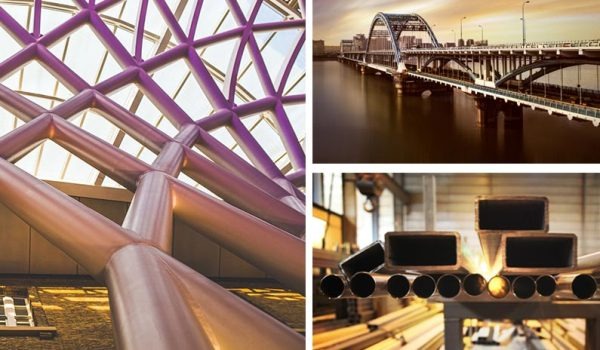

Where Speed Matters Most—Industry Applications

The G Series high-speed tube laser cutting machine shines in industries where speed, precision, and flexibility are paramount. According to Hymson's product documentation and typical customer use cases, the following industry sectors derive maximum value from the G Series:

- Metal Furniture & Home Decor

High-speed cutting ensures timely delivery of custom frames, table legs, shelving tubes, and curved furniture profiles. With automatic loading and nesting, small-lot batch orders become easy to handle.

- Smart Building Components

From curtain wall structures to pipeline supports, the G Series processes complex angles and thick tubes quickly, enabling shortened project cycles for construction or smart city infrastructure.

- Engineering Machinery

In construction machinery, bulk delivery of precision-cut rectangular and circular tubes significantly boosts frame assembly efficiency. The robustness of the Hymson G Series allows for heavy-duty tubing operations.

- Electrical Cabinets and Energy Systems

The clean and precise cuts from the G Series prevent welding defects in frame installations for switch cabinets and energy systems. Rounded edges and burr-free finishes eliminate additional reprocessing.

- Bathroom & Kitchen Hardware

For stainless steel or aluminum alloys used in bathroom appliances and kitchen devices (e.g., shower poles, towel racks, sink supports), the G Series performs complex notch and slot cutting in seconds.

- Automotive & New Energy Vehicles

The machine’s capability to cut long tubes and create multi-angled hole patterns is ideal for lightweight EV components, chassis beams, and internal pipe routing in precision automotive structures.

- Oil/Gas Pipelines & Petrochemical Industry

For heavy-wall or mid-diameter metal pipes used in pipeline transport and refinery plant fabrication, the G Series offers excellent cut consistency with minimal heat-affected zones.

- Shipbuilding and Aerospace

In both industries, precision and speed are essential. The G Series supports long-length aluminum or ship-grade steel cutting, often with variable cross-sections or multi-hole precision drilling.

Each of these sectors shares one thing in common: the need to shorten lead time without compromising quality. The Hymson G Series delivers exactly that by combining cutting-edge speed with multi-profile adaptability.

Conclusion: Faster Isn’t Just Better—It’s Smarter

In this era of industrial transformation, speed equals competitiveness. But speed without stability, flexibility, and precision means nothing. The Hymson G Series tube laser cutting machine offers all four—making it a top choice for manufacturers and agents worldwide.

Whether you’re optimizing for mass production or flexible customization, this high-speed system provides the automation agility required to keep your operation ahead of the curve.

FAQs – Frequently Asked Questions

Q1: How fast can the Hymson G Series cut compared to a normal saw or plasma?

A1: Up to 5–7 times faster, with speeds reaching 100 m/min.

Q2: Does faster speed compromise accuracy?

A2: Not with Hymson. Its systems maintain ±0.03 mm precision even at high-speed operations.

Q3: What pipe shapes and sizes are supported?

A3: Round, square, rectangular, oval, and even customized complex profiles.

Q4: Can a beginner operator run this machine?

A4: Yes. It’s highly automated with a user-friendly interface and full training support provided.

Q5: Is it compatible with smart factory or MES integration?

A5: Absolutely. Hymson offers seamless control system integration compatible with Industry 4.0 production environments.

Share This Post: