As global manufacturing rapidly evolves in the direction of digitalization, precision, and automation, selecting the right laser cutting machine becomes a strategic decision for modern manufacturers, integrators, and distributors. CNC fiber laser cutting machines are now the gold standard for cutting metals—offering unmatched efficiency, precision, and versatility. Whether you process sheet metal, tube profiles, or complex structural components in sectors such as electric power, automotive, smart furniture, or heavy machinery, making the right equipment choice in 2025 is essential for operational success.

Table of Contents:

What is a CNC Fiber Laser Cutting Machine?

Core Components of CNC Fiber Laser Cutting Machine

Pros of CNC Fiber Laser Cutting Machine

Versatile Application Fields in 2025

6-Step Guide: How to Choose the Right CNC Fiber Laser Cutting Machine?

Why Does Hymson Laser Stand Out Among Manufacturers?

Final Thought

FAQs --- CNC Fiber Laser Cutting Machine

What is a CNC Fiber Laser Cutting Machine?

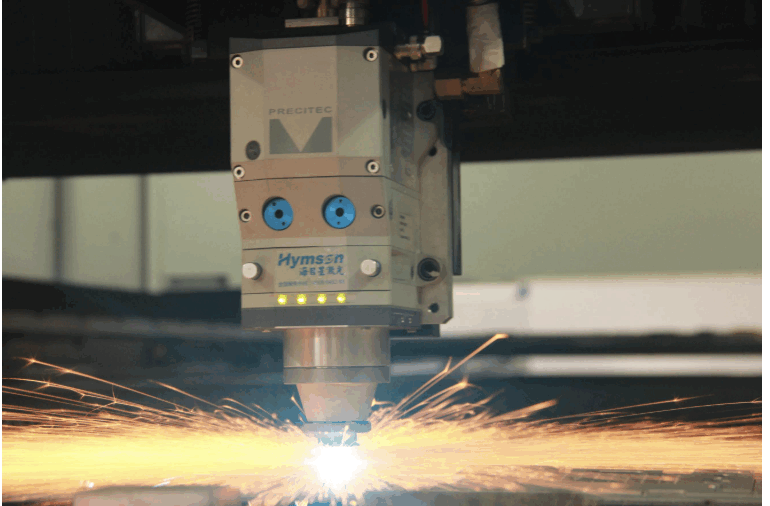

A CNC (Computer Numerical Control) fiber laser cutting machine is an advanced piece of industrial machinery that uses a high-powered fiber laser beam to cut metals with exceptional precision. Unlike traditional CO₂lasers or plasma cutters, fiber lasers use a solid-state laser source transmitted via fiber optics, allowing for faster cutting speeds, lower maintenance, and suitability across a wide range of conductive materials such as stainless steel, carbon steel, aluminum, brass, and copper.

The machine is typically composed of a laser generator, cutting head, CNC control system, servo motors, transmission systems, machine bed, and cooling components. All are seamlessly integrated to ensure precise, stable, and automated operation even under high-throughput production environments.

Core Components of CNC Fiber Laser Cutting Machine

Every part of a fiber laser cutting machine plays a crucial role in performance, lifetime durability, and quality of the final product. Here’s a breakdown of the key components you should evaluate:

|

Component |

Key Feature |

Impact on Performance |

|

Laser Source |

Power ranging from 1 kW to 30 kW+ |

Defines cutting speed and material thickness |

|

Cutting Head |

Adjustable focus, sensor feedback |

Ensures accuracy and clean edges |

|

CNC Controller |

Integrated software & command system |

Drives machine programming and precision |

|

Machine Bed |

Welded/cast iron with anti-vibration |

Affects high-power cutting stability |

|

Transmission System |

Rack & pinion or linear guideways |

Optimizes speed and axis precision |

Pros of CNC Fiber Laser Cutting Machine

CNC fiber laser cutters are popular because they dramatically improve efficiency, reduce operational costs, and deliver clean, burr-free metal processing. Compared to conventional cutting tools:

- Operation is faster and less labor-intensive

- Precision is higher across varied thicknesses

- Maintenance costs are significantly lower

- The system integrates easily with smart factory solutions

They are especially welcomed by industries that demand flexibility, such as rapid product development lines, custom furniture manufacturers, or aerospace contractors.

Versatile Application Fields in 2025

In 2025, fiber laser cutters are central to nearly every modern industrial manufacturing segment due to their universal adaptability. Typical applications include:

|

Industry |

Application Example |

Recommended Configuration |

Industry |

|

Sheet Metal Fabrication |

Cabinets, machine housings |

3 kW–6 kW flatbed laser |

Sheet Metal Fabrication |

|

Automotive Industry |

Body panels, exhaust systems |

6 kW+ flat/tube combination |

Automotive Industry |

|

Power Equipment |

Enclosures, switchboards |

8–15 kW large-size model |

Power Equipment |

|

Kitchen & Furniture |

Stainless/chrome decorative panels |

3–6 kW compact system |

Kitchen & Furniture |

|

Aerospace & Precision |

High-alloy lightweight parts |

12 kW+ with fine cutting head |

Aerospace & Precision |

6-Step Guide: How to Choose the Right CNC Fiber Laser Cutting Machine?

Making the right purchasing decision can be complex. Here’s a step-by-step roadmap:

- Define your material and cutting thickness demand

Determine whether you'll be processing carbon steel, stainless steel, aluminum, brass, or mixed materials.

- Specify your daily/weekly production requirements

How many parts will you cut per shift? Will you need automated loading and unloading to meet demand?

- Choose your laser power wisely

1 kW–3 kW for thin sheets; 6kW+ for medium thickness; 10 kW+ for heavy/industrial use.

- Select the proper bed size & automation level

Small-format machines for compact parts; dual-platform automated models for high volume.

- Compare technical support and warranty terms

Evaluate spare availability, remote diagnostics, and local agent support.

- Request sample tests, technical consultation, and quotation

Reputable manufacturers like Hymson Laser will offer free testing, walk-through demos, and consulting to find your best fit.

Why Does Hymson Laser Stand Out Among Manufacturers?

Hymson Laser distinguishes itself in the global fiber laser cutting equipment market through its strong industry experience, advanced technological capabilities, and comprehensive automation solutions tailored to the evolving needs of modern manufacturing. As a leading laser equipment manufacturer headquartered in Shenzhen, China—with multiple R&D and production bases in Jiangsu, Jiangmen, and Anshan—Hymson has developed a robust global presence with subsidiaries and service centers in Italy, the United States, South Korea, and beyond. The company is renowned for its commitment to innovation, offering not only high-performance CNC fiber laser cutting machines but also fully integrated “laser + automation” smart factory solutions. Hymson's solid engineering foundation, professional technical services, and dedication to customer success make it a trusted long-term partner for manufacturers, resellers, and integrators worldwide.

Key advantages of choosing Hymson Laser:

- End-to-End Solutions: From flat sheet cutters to tube lasers, 3D cutting systems, and intelligent welding equipment, Hymson provides comprehensive equipment and automated production line integration.

- Global Support Network: With over 2,000 employees and localized service teams in key regions, they ensure fast response, installation, and training.

- Self-Developed Control Systems: Homegrown CNC systems and optimization software ensure performance and process stability.

- Smart Manufacturing Ready: MES platform integration, visual guidance, automatic loading/unloading, and digital twin technologies.

- Wide Application Success: Real-world cases across automotive, furniture, sanitaryware, shipbuilding, aerospace, and more.

Final Thought

Choosing the right CNC fiber laser cutting machine in 2025 is not just a technical decision—it’s a strategic investment in your factory’s future. By evaluating your production needs, matching machine capabilities, and partnering with an experienced and supportive vendor like Hymson Laser, you position your business for greater efficiency, flexibility, and success in an increasingly competitive industrial landscape.

Now is the time to consider modernizing your production with high-performance fiber laser cutting technology. Contact Hymson Laser for a consultation, free sample test, or customized quotation tailored to your application.

FAQs --- CNC Fiber Laser Cutting Machine

Q1: What power fiber laser cutting machine do I need to cut 10–20mm stainless steel?

A1: You'll need a machine rated between 6kW and 12kW depending on precision and speed demands.

Q2: Can a fiber laser handle both flat sheets and tubes?

A2: Yes, combination machines (flat-tube dual-use) are ideal for fabricators needing multi-form processing.

Q3: Which laser brand is better—IPG or Raycus?

A3: IPG offers higher reliability for continuous operation, while Raycus provides excellent value performance.

Q4: Can I integrate the cutting machine with my MES or ERP system?

A4: Yes, smart-ready systems like Hymson machines are built for Industry 4.0 integration.

Q5: Does Hymson offer overseas customer support and training?

A5: Absolutely. With regional offices and partners abroad, Hymson provides on-site assistance, training, and after-sales support.

Share This Post: