When "Growth" Becomes a Problem

For a growing metal fabrication company, nothing is more frustrating than having a steady stream of orders while the production line is overwhelmed. When your press brakes are idle, your welding team is waiting for parts, and your delivery times are slipping, the root of the problem often points to the very first step in your process: the cutting stage.

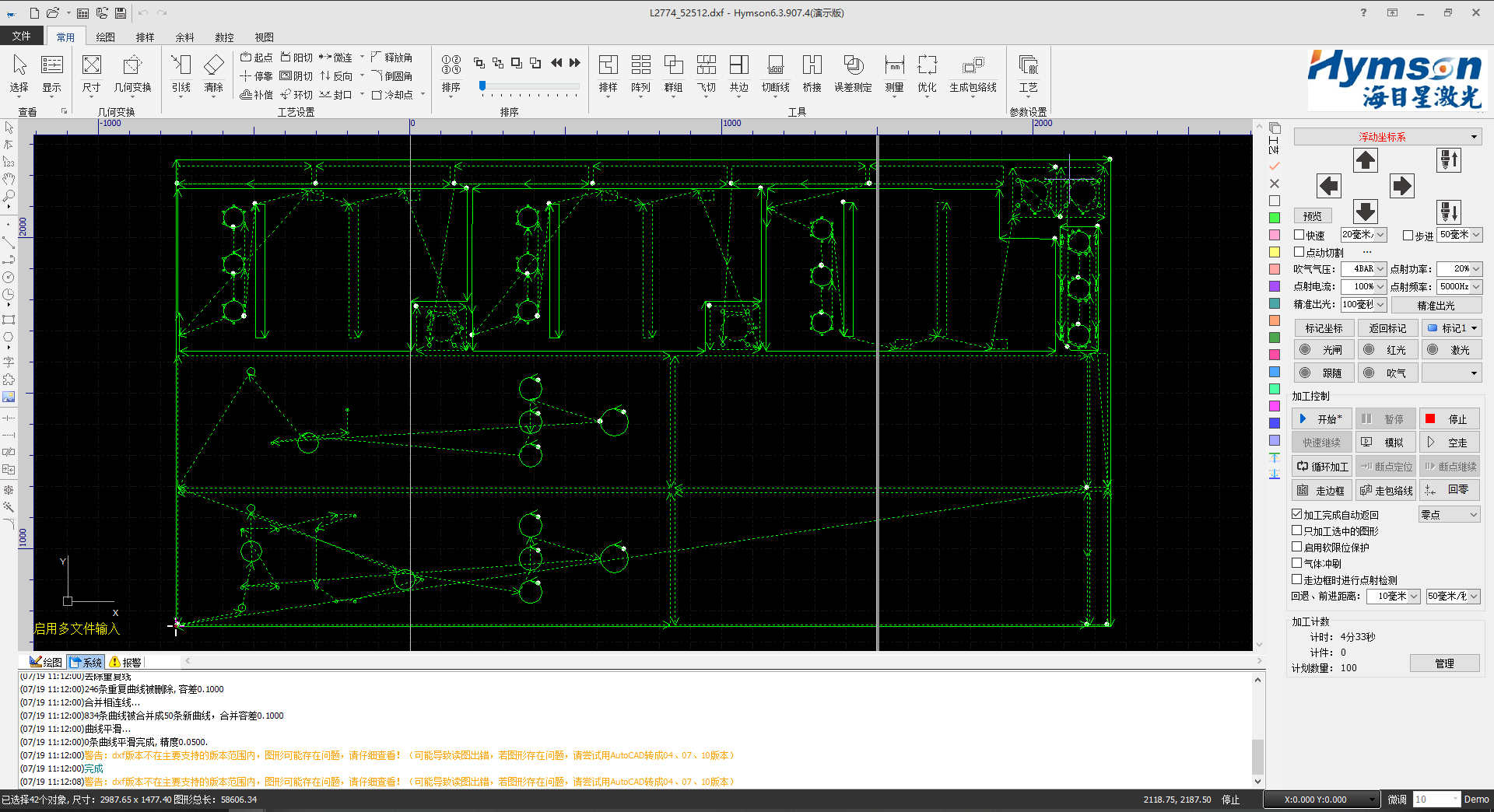

This initial phase is quietly becoming the "capacity ceiling" that limits your company's entire potential for growth. This article will explore this common operational bottleneck and analyze how a Hymson high-speed fiber laser cutter can fundamentally shatter this constraint, transforming your "production bottleneck" into a "growth engine."

Part 1: Diagnosing Your Bottleneck – The Three Layers of the Problem

The most obvious symptom of a bottleneck is that it's "slow," but the issue runs deeper.

Symptom 1: The "Illusion of Speed" on Complex Jobs

Many machines perform adequately when cutting long, straight lines. However, their true efficiency plummets when faced with complex parts full of small contours and sharp corners (e.g., machine components, decorative panels). The frequent acceleration, deceleration, and poor cornering control lead to massive amounts of non-cutting time. This is what truly consumes your production capacity.

Symptom 2: Unpredictable Downtime

A bottleneck is disruptive because it's unstable. If a cutting machine loses accuracy due to thermal deformation from long hours of operation, it requires frequent shutdowns for recalibration and often produces scrap. This cycle of "stop and fix" not only disrupts the production schedule but also leaves downstream processes waiting indefinitely.

Symptom 3: Misallocation of Human Resources

When the cutting stage is the bottleneck, your most skilled technicians may be forced to spend their valuable time on simple loading/unloading tasks or monitoring an unreliable machine. This is not just a waste of labor costs; it's a drain on your core competitive advantage.

Part 2: The Solution – Clearing the Path with a Strategic Tool

Solving a bottleneck requires a systematic solution, not just a quick fix. The Hymson high-speed cutter is engineered precisely for this purpose.

1: Achieving True Efficiency on Complex Tasks

The Solution: The combination of 1.5G maximum acceleration and 7Hz low-pass filtering technology.

The Operational Impact: High acceleration means the machine can start, stop, and change direction between short segments and corners with incredible speed, drastically compressing non-cutting time. This ensures its "effective cutting efficiency" on complex jobs is far superior to standard machines with similar specs. Your production line will no longer slow down due to the complexity of an order.

2: Ensuring "24/7" Stable Output

The Solution: A heavy-duty machine bed treated with high-temperature annealing and active thermal dynamic compensation technology.

The Operational Impact: A rock-solid physical foundation combined with an intelligent, self-correcting system ensures the machine maintains micron-level cutting accuracy, even during continuous, high-intensity operation. This means you can confidently schedule production runs back-to-back, achieving perfect consistency from the first part to the last and eliminating downtime and scrap caused by machine instability.

3: Paving the Way for Automation and Freeing Up Your Team

The Solution: The FSCUT control system, based on the EtherCAT bus, provides a seamless interface for automation integration.

The Operational Impact: This machine was designed from the ground up to be more than a standalone unit; it is the core of a future automated production line. By integrating with an automatic loading and unloading system, it can easily achieve continuous, unattended production. The process that once required constant supervision can now be handled automatically, allowing your team to focus on higher-value work like programming, quality control, and process optimization.

Part 3: "Before" and "After" – A Real-World Picture of Unlocked Capacity

Imagine this scenario:

Before: Your factory cuts 50 project units per day. Your downstream bending and welding teams are limited to this pace, and your lead time is 3 days. To meet deadlines, you run two shifts, but the cutting station remains the most stressed part of the entire factory.

After: With the Hymson high-speed cutter, the same 50 project units are finished in just half a shift. Your cutting process is transformed from a bottleneck into a capacity reserve. Now you can:

- Accept double the orders without increasing work hours.

- Shorten lead times from 3 days to 1.5 days, giving you a key competitive advantage.

- Optimize production rhythm, allowing downstream processes to finally operate at full capacity and boosting the entire factory's operational efficiency.

An Investment in Your Machine, and Your Factory's Future

Breaking through your capacity ceiling requires more than just determination; it requires the right tools. The Hymson high-speed fiber laser cutter offers a strategic leverage point for growing businesses through its superior efficiency, extreme stability, and future-proof automation capabilities.

It doesn't just solve a problem at the cutting stage; it revitalizes the entire production chain by clearing the most critical bottleneck. It turns potential orders into real profit and ensures that on your path to growth, you will have no obstacles holding you back.

If your business is facing a similar growth struggle, it's time to re-evaluate the core of your production line.

Share This Post: