In 2025, the global manufacturing landscape is being reshaped by a convergence of automation, digitalization, and green technology. At the heart of this transformation is laser technology—a key enabler for faster production, higher precision, and smarter processes. From metal fabrication to battery assembly, laser systems are no longer optional equipment; they are a cornerstone of the smart factory.

Hymson Laser, a leader in industrial laser equipment and intelligent automation solutions, plays a pivotal role in this transformation by equipping manufacturers with cutting-edge fiber lasers, laser welding platforms, and fully automated production lines. This article explores how laser technology is transforming key manufacturing sectors and why it's central to the future of global industry.

Evolution from Traditional to Laser-Based Manufacturing

Then vs Now

- Manual processing, mechanical cutting, and welding have long been industry standards

- Limitations: low precision, high waste, longer cycle times

- Transition: Adoption of laser systems for higher speed, automation readiness, and digital compatibility

Hymson's Role

- From simple laser cutters to full-stack smart laser lines

- Enabling thousands of factories worldwide to modernize operations with digital-ready laser solutions

Core Advantages of Laser Technology in 2025

Speed and Throughput

High-speed cutting, welding, and marking

Less downtime due to non-contact processing

Precision and Consistency

- Beam quality allows for micro-level accuracy

- Reduced deformation and heat-affected zones

Flexibility Across Materials

- From stainless steel to aluminum and composite metals

- Laser settings can be digitally adjusted for different thicknesses and part geometries

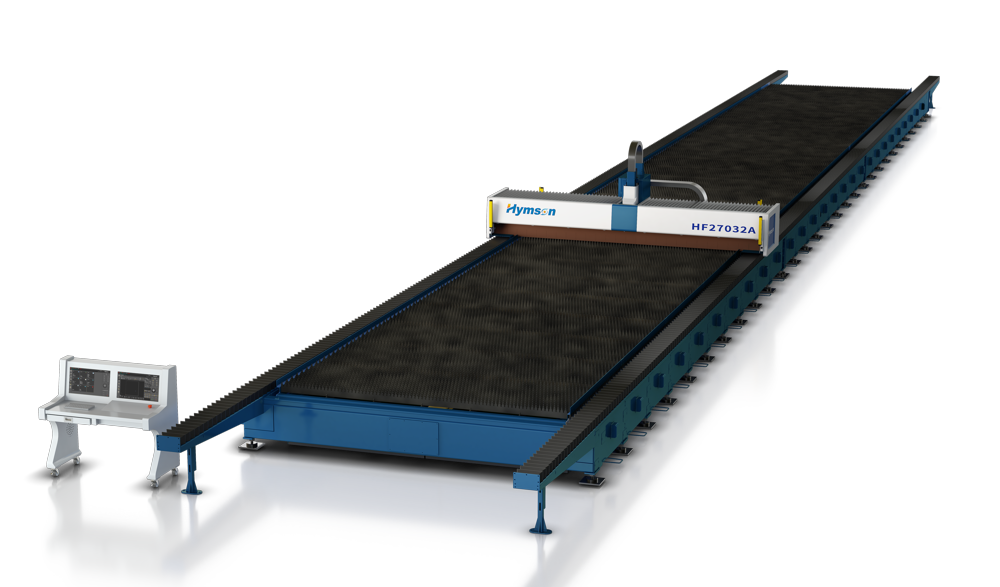

Hymson's fiber laser cutting machines, like the H Series and G Series, are widely adopted in elevator manufacturing and cabinet industries due to their ultra-high speed and precision.

Digital Integration and Smart Factory Compatibility

Key Technologies

- IoT-enabled laser machines with real-time performance monitoring

- MES/ERP integration for traceability

- Vision systems for auto-alignment and adaptive processing

Hymson's Innovation

- Laser automation lines with robotic arms, smart sensors, and software control

- Customers using Hymson's integrated systems report up to 40% increase in production efficiency

Industry-Specific Transformations

Automotive Industry

- Laser welding of battery trays, BIW (Body-in-white) structures, and precision cutting for lightweight frames

- Hymson's fully enclosed fiber laser systems ensure clean-room level operations for EV components

EV Battery Manufacturing

- Hairpin welding, tab welding, and structural seam welding

- Seam tracking and real-time quality control embedded in Hymson’s battery laser welding platforms

Sheet Metal and Cabinetry

- Customizable cutting heads and high-speed motion control

- Mass production of electrical enclosures and elevator panels

Automation and Modular Manufacturing

- Modular laser lines with auto-loading, conveyor-based transfer, and robot-assisted welding

- “Lights-out” manufacturing enabled by Hymson’s smart factory modules

- Easy changeovers for small-batch and multi-type production

Case Example: A household appliance manufacturer reduced manpower by 50% and increased yield by 25% after implementing a Hymson smart laser automation line.

Sustainability and Cost Efficiency

Environmental Gains

Less material waste, fewer consumables

Cleaner production with reduced emissions compared to plasma/oxy-fuel processes

Economic Impact

- Reduced power consumption (especially with fiber laser systems)

- Lower cost per part over time

Hymson’s green manufacturing vision supports both cost control and ESG compliance for global exporters.

The Future Outlook: What's Next?

- High-power multi-axis lasers for thicker and hybrid materials

- AI-driven quality control and predictive maintenance

- Greater customization via software-driven laser modulation

- Cloud-based fleet management of laser equipment across multiple factories

Hymson Laser’s R&D teams are actively developing next-gen laser solutions that align with evolving customer needs in EV, aerospace, and consumer electronics.

Why Manufacturers Choose Hymson Laser

| Feature | Hymson Advantage |

| Full-solution Integration | Machines + software + robotics + automation |

| Industry Experience | Proven success in EV, cabinet, elevator, and metal sectors |

| Custom Engineering | Tailored systems based on customer application |

| Global Support Network | Pre-sales consulting + after-sales service + local presence |

Conclusion

Laser technology is not just enhancing existing manufacturing methods—it is redefining what is possible in 2025 and beyond. Whether you are producing EV batteries, processing stainless steel enclosures, or aiming to upgrade to a smart production line, laser systems are essential.

Hymson Laser delivers intelligent, high-performance laser solutions tailored to the unique needs of modern manufacturers. As a trusted partner in your digital transformation journey, we provide not just equipment, but a roadmap to long-term competitiveness.

Share This Post: