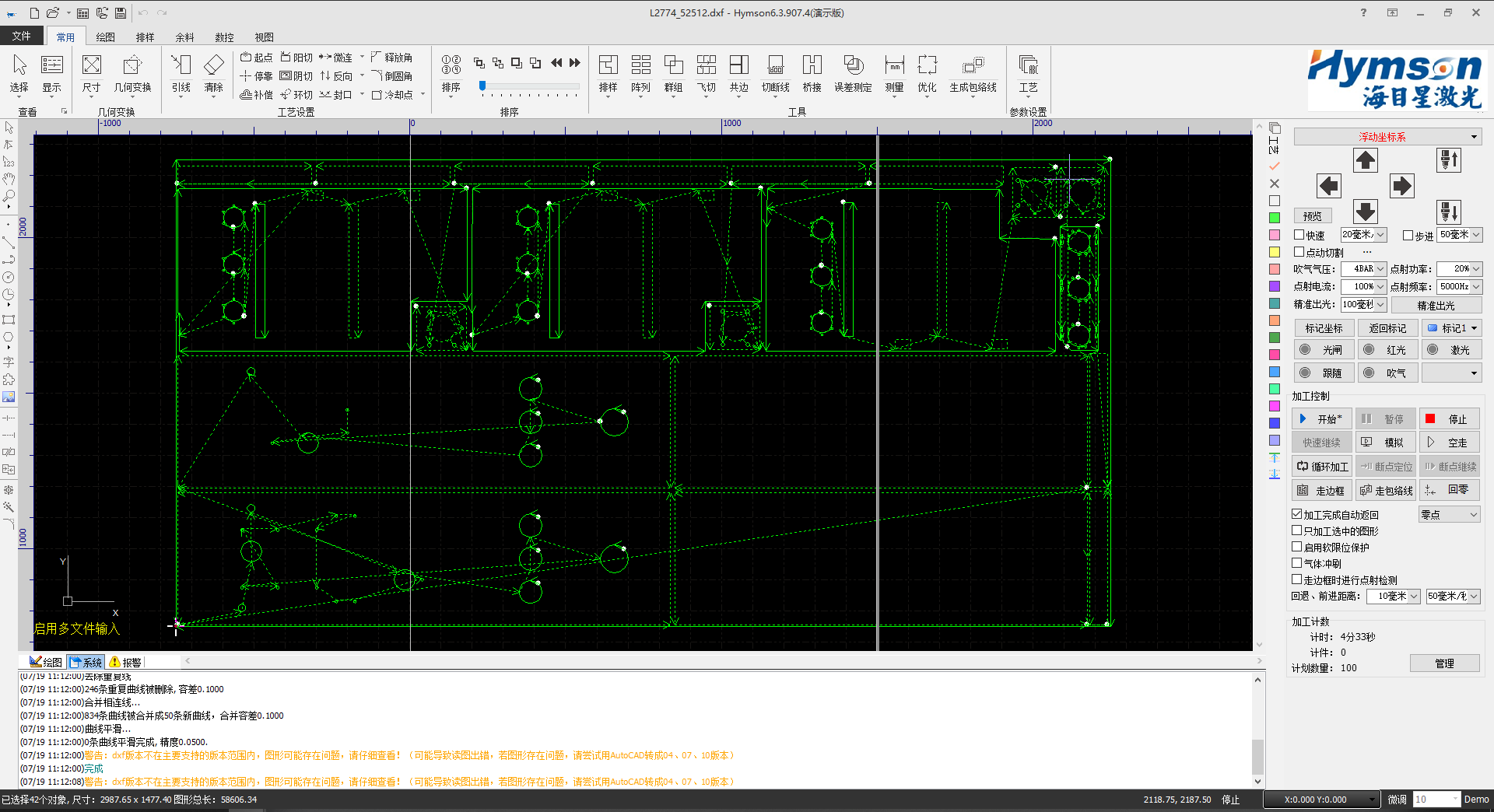

For any production manager, engineer, or business owner in the metal fabrication industry who pursues high efficiency and precision, selecting the right laser cutting machine is a critical decision. This article provides an in-depth analysis of Hymson's high-speed fiber laser cutting machine, aiming to answer the most pressing questions for potential users: What are its key technologies? How do these technologies translate into tangible production benefits? And what production scenarios is it best suited for?

Core Question 1: How to Balance Cutting Speed with Cornering Precision?

In actual production, "high speed" alone is meaningless, especially when cutting complex patterns or parts with sharp corners. If the machine cannot effectively control its speed and acceleration at corners, it can easily lead to over-burning or deformation, compromising the quality of the finished product.

This high-speed cutting machine addresses this challenge through a combination of two key technologies:

- 1.5G Maximum Acceleration: High acceleration means the cutting head can reach and depart from its target speed more quickly. When processing numerous short line segments and complex contours, this significantly reduces non-cutting wait times, directly boosting overall processing efficiency.

- 7Hz Low-Pass Filtering: This is a crucial control technology. It "smooths out" the vibrations and shocks of the machine during high-speed motion, particularly when rapidly changing direction at corners. The 7Hz filtering frequency ensures that the machine can execute the cutting path with precision while maintaining high speed (1.5G acceleration), resulting in corner quality that is both fast and smooth.

Conclusion: This cutting machine does not blindly chase speed. Instead, it uses a combination of "high acceleration + intelligent filtering" to maximize effective production efficiency while guaranteeing the quality of complex part processing.

Core Question 2: How to Ensure Stability and Consistency in Long-Term, High-Volume Production?

It's not difficult for a machine to perform well during its initial setup. The real test is whether it can maintain the same cutting accuracy after operating continuously for hours or even days. Heat is the primary enemy of stability.

This machine provides two layers of protection to address this:

-

Structural-Level Thermal Protection and Stress Relief:

- Machine Bed: Constructed from high-strength welded steel plates, it undergoes a high-temperature annealing process. The purpose of this procedure is to eliminate the internal stresses generated during welding, preventing the machine bed from undergoing micro-deformations due to temperature changes over time. This fundamentally ensures the long-term structural stability.

- Protection: The interior is lined with custom high-temperature resistant materials, providing 360° all-around thermal protection that effectively isolates the machine structure from the heat generated by high-power cutting.

-

Technology-Level Active Compensation:

- Thermal Dynamic Compensation Technology: This is an intelligent, active error-correction function. The system monitors minute changes in the equipment caused by heat and applies real-time compensation to the processing parameters. This ensures that every part, from the first to the last, is cut with the same level of precision.

Conclusion: Through a combination of "passive physical protection + active intelligent compensation," this equipment aims to solve the most persistent problem in mass production—accuracy consistency—thereby reducing the scrap rate and guaranteeing delivery quality.

Core Question 3: How Do the Core Components Perform? Is It Easy to Maintain and Integrate?

The long-term reliability of a machine depends on the quality of its core components and the soundness of its overall design.

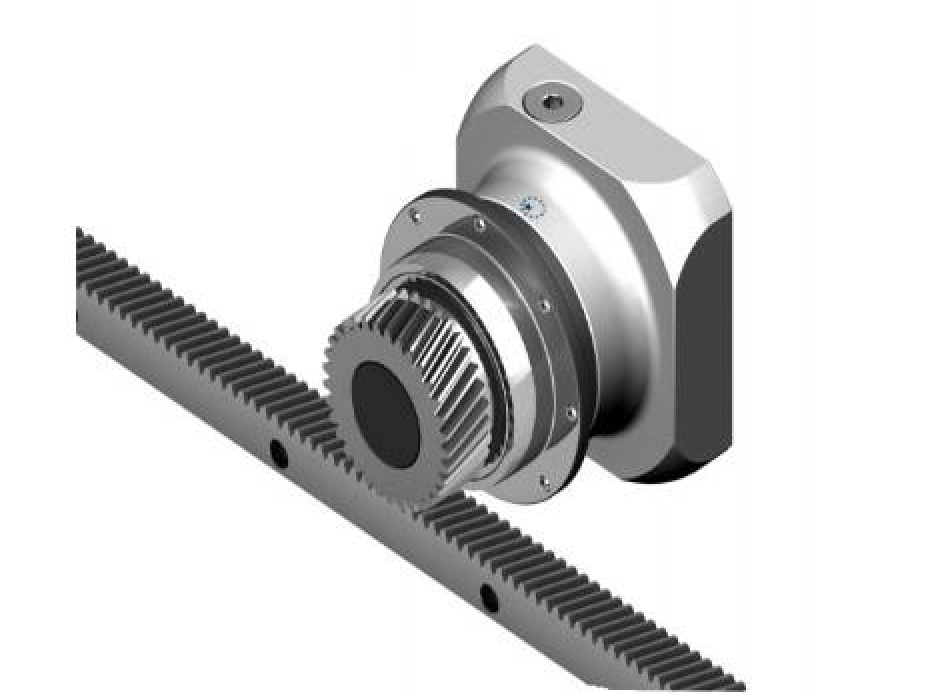

- Drive System: It utilizes a precision-ground rack and pinion system with a dual-drive gantry structure. This design offers better meshing and driving force, effectively reducing vibration and providing the physical foundation for achieving 1.5G high acceleration.

- Beam: It features a patented Hymson drawn aluminum beam. Its advantages lie in being both "lightweight" and "rigid." Being lightweight reduces the load on the motors for a higher dynamic response, while high rigidity ensures it does not deform during high-speed movement, guaranteeing cutting accuracy.

- Control System (FSCUT): This is the brain of the machine. Based on EtherCAT bus control, it has an extremely short response time (≤100us), ensuring fast and precise execution of commands. More importantly, it provides interfaces for seamless integration with automatic loading/unloading systems and FMS flexible manufacturing systems, leaving room for future intelligent upgrades.

- Operating Cost Consideration (Zoned Dust Extraction): Conventional, full-area dust extraction systems consume high energy and are often inefficient. The machine's zoned dust extraction system only activates suction in the area where the cutting head is currently working. This results in a shorter path and stronger suction force, leading to better dust removal with lower energy consumption.

Technical Specifications Overview

Below are the key parameters for the two main models, allowing for direct comparison and workshop planning.

| Equipment Model | HF3015G | HF4020G |

| Effective Cutting Range | 3100mm x 1550mm | 4000mm x 2000mm |

| X/Y-axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| Maximum X/Y-axis Acceleration | 1.5g | 1.5g |

| Maximum Z-axis Positioning Speed | 40m/min | 40m/min |

| Floor Space of Whole Machine | 8700mm x 2800mm | 10800mm x 3500mm |

This Hymson high-speed fiber laser cutting machine is not merely an assembly of high-performance hardware. It is a systematic solution that addresses the core pain points of efficiency, precision, stability, and long-term operating costs in the manufacturing industry through a series of interconnected technologies and structural designs. It is particularly well-suited for metal fabrication businesses that have high standards for processing quality and production efficiency, and that require a machine capable of long-term stable operation with the potential for future automation upgrades.

Share This Post: