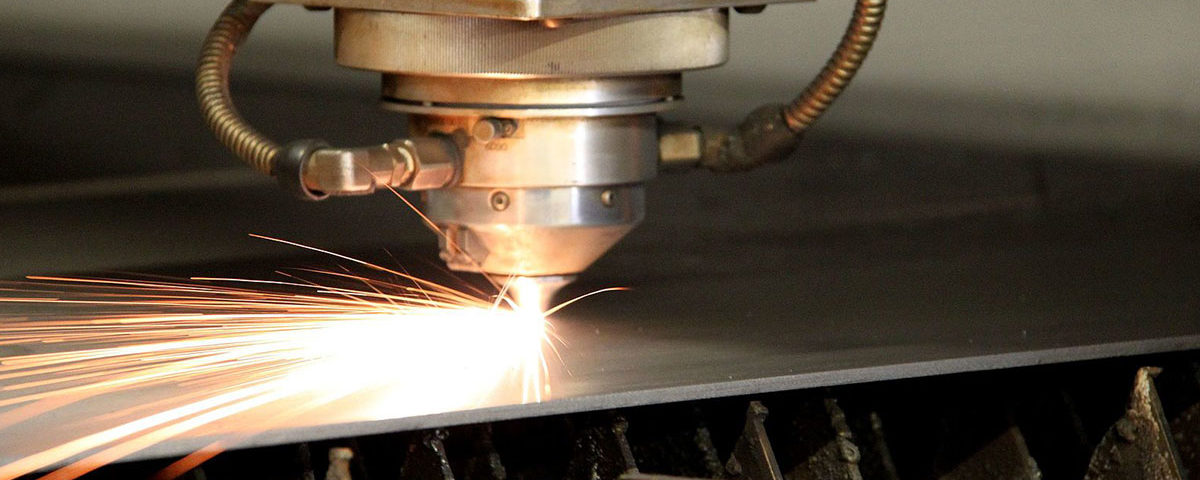

Traditional methods like stamping and shearing have long been the workhorses of the industry. However, they often face limitations when dealing with complex designs, tight tolerances, and diverse materials. In contrast, laser cutting uses a highly focused beam of light to precisely melt, burn, or vaporize the material. This process results in exceptionally clean and smooth edges that are free of burrs, significantly reducing the need for secondary finishing work and saving both time and money.

The growing popularity of laser cutting is driven by advancements in laser technology, sophisticated control systems, and automation. Fiber lasers, in particular, have become the preferred choice due to their high power, efficiency, and superior beam quality. They can effortlessly cut through a wide variety of materials, including steel, stainless steel, aluminum, and copper, with remarkable speed and accuracy.

Key Advantages of Laser Cutting

1. Precision and Accuracy: Laser cutting excels when it comes to precision, making it the ideal choice for intricate designs and projects with strict tolerance requirements. The focused laser beam allows for incredibly accurate cuts with a minimal heat-affected zone, preventing material distortion. This is critical for applications where exact dimensions are paramount, such as in aerospace components, medical devices, and sensitive electronic enclosures.

2. Cost-Effectiveness: A Smart Long-Term Investment While the initial investment in laser cutting equipment may be higher than traditional machinery, the long-term savings are substantial. Laser cutting eliminates the need for custom tooling for different designs, which greatly reduces setup times and tooling costs. The highly automated process also minimizes labor expenses and increases production speed. Furthermore, the clean cuts often remove the need for secondary processes like deburring, leading to further cost reductions.

3. Speed and Efficiency: Accelerating Production Laser cutting is significantly faster than many conventional methods, especially for complex shapes. The high-speed capabilities of modern machines allow manufacturers to produce parts quickly, shortening lead times and boosting overall productivity. The automation also enables "lights-out" manufacturing, where machines can run unattended, maximizing utilization and efficiency.

4. Versatility Materials: Laser cutting is not limited to just a few materials. It can effectively process a wide array, including steel, stainless steel, aluminum, copper, and brass. It also handles a broad range of thicknesses, from thin gauge sheets to thicker plates. This versatility makes it a valuable solution for diverse applications across many industries.

5. Complex Geometries and Creative Freedom: Laser cutting opens the door to fabricating complex shapes, intricate patterns, and fine details that would be difficult or impossible to achieve with other methods. The precise control of the laser beam allows for the creation of sharp corners, tiny holes, and elaborate designs with exceptional accuracy. This is especially beneficial for custom or decorative components, such as architectural panels and artistic signage.

6. Automation and CNC Control: Laser cutters are integrated with CNC (Computer Numerical Control) systems, which enable fully automated operation and precise control over the cutting process. CNC programming allows manufacturers to execute complex cutting paths and ensure consistent quality across large production runs, while minimizing the risk of human error.

7. Minimal Material Waste: Laser cutting is a highly efficient process that minimizes material waste. The narrow cut width, or "kerf," allows for the tight nesting of parts on a single sheet, maximizing material utilization and reducing scrap. This is particularly important when working with expensive materials like stainless steel and aluminum.

8. Clean, Burr-Free Edges: One of the most significant benefits of laser cutting is the high-quality finish it produces. The process creates clean, smooth, and burr-free edges, often eliminating the need for secondary finishing. This is crucial for applications where aesthetics and safety are important, such as in consumer electronics and medical equipment.

Typical Applications of Laser Cutting in Sheet Metal

Laser cutting technology is used across a vast spectrum of industries:

- Automotive: Body panels, chassis components, interior trim

- Aerospace: Structural components, engine parts, interior panels

- Electronics: Enclosures, brackets, heat sinks

- Medical Devices: Surgical instruments, equipment housings

- Construction: Architectural panels, roofing systems, structural parts

- Signage: Custom signs, displays, lettering

- General Manufacturing: Machine components, tools, and fixtures

- Art & Design: Decorative screens, sculptures, custom artwork

How to Choose the Right Laser Cutting Service Provider?

Selecting the right partner is crucial for your project's success. Here are key factors to consider:

- Experience and Expertise: Look for a provider with a proven track record of delivering high-quality laser cutting services. Inquire about their experience with your specific materials and design complexity.

- Equipment and Technology: Ensure they use modern, well-maintained equipment, including advanced fiber lasers and reliable CNC systems capable of meeting your project's demands.

- Material Capabilities: Confirm that the provider can handle the materials and thicknesses your project requires, including steel, aluminum, stainless steel, and other alloys.

- Design and Engineering Support: A valuable partner can offer design optimization advice to improve manufacturability and reduce costs.

- Quality Control: The provider should have a robust quality control system to inspect parts and verify that they meet your exact specifications.

- Turnaround Time: Discuss your project timeline and confirm they have the capacity to meet your deadlines efficiently.

- Pricing: Obtain quotes from several providers and compare them based on overall value, which includes quality, service, and delivery time.

- Customer Service: Choose a provider that is responsive, communicative, and committed to ensuring your satisfaction throughout the process.

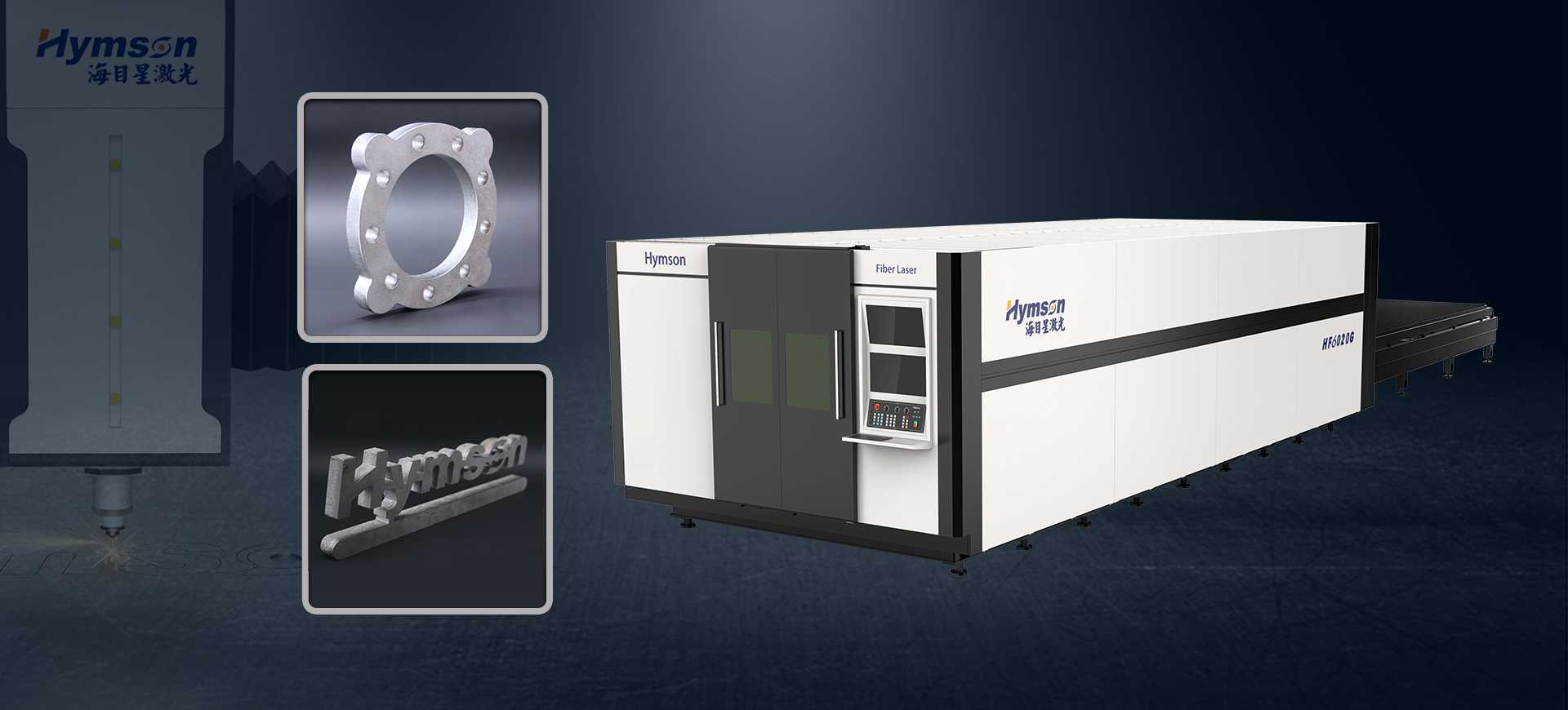

Hymson: Your Trusted Partner for Precision Laser Cutting

At Hymson, we understand the critical importance of precision, quality, and reliability in sheet metal fabrication. We offer comprehensive laser cutting solutions using state-of-the-art fiber laser technology. Our experienced team of engineers and technicians is committed to delivering exceptional results that meet your exact requirements.

We operate multiple fiber lasers capable of processing mild steel up to 1 inch (25.4 mm) thick, with a maximum sheet size of 60" x 120" (1524 x 3048 mm). We work with a wide range of materials, including steel, aluminum, and stainless steel. Our CNC-controlled machines ensure consistent quality and accuracy, even on large production runs.

We are dedicated to providing our customers with:

- High-precision laser cutting for exceptional accuracy and tight tolerances.

- Fast turnaround times to meet your project deadlines.

- Competitive pricing for cost-effective solutions without compromising on quality.

- Excellent customer service and support throughout your entire project.

Laser cutting has transformed the sheet metal fabrication industry by offering an unmatched combination of precision, speed, versatility, and cost-effectiveness. By understanding its advantages and carefully selecting a professional service provider, you can significantly enhance your manufacturing processes, improve product quality, and reduce overall costs. Contact Hymson today to discover how our precision laser cutting services can help your business succeed.

Share This Post: