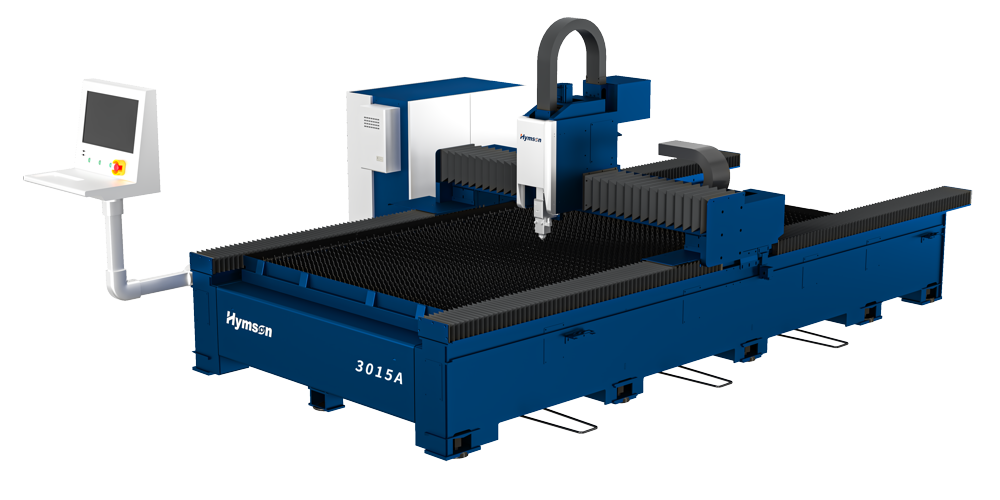

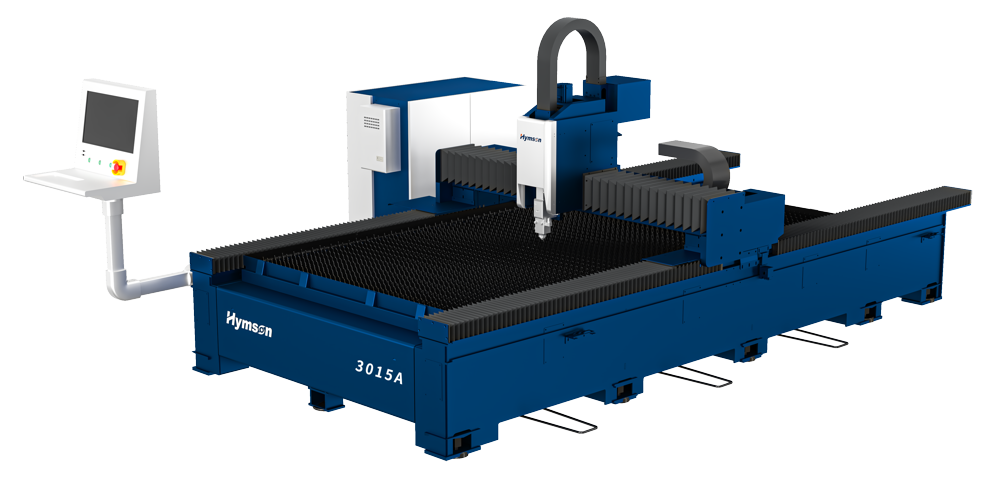

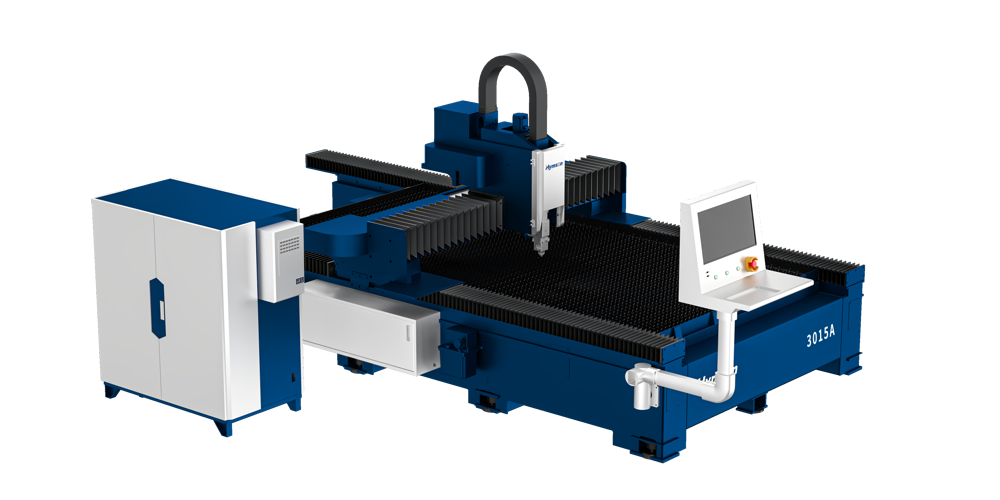

Fiber Laser Cutting Machine - HF-A Series

HF·A Series is a Hymson single table fiber laser cutting machine.

- High speed and high precision cutting of medium and thin carbon steel, stainless steel and aluminium plates.

- High-precision movement and high-speed perforation.

- High-strength structure and intelligent ventilation structure guarantee the equipment long-term stable operation and production safety.

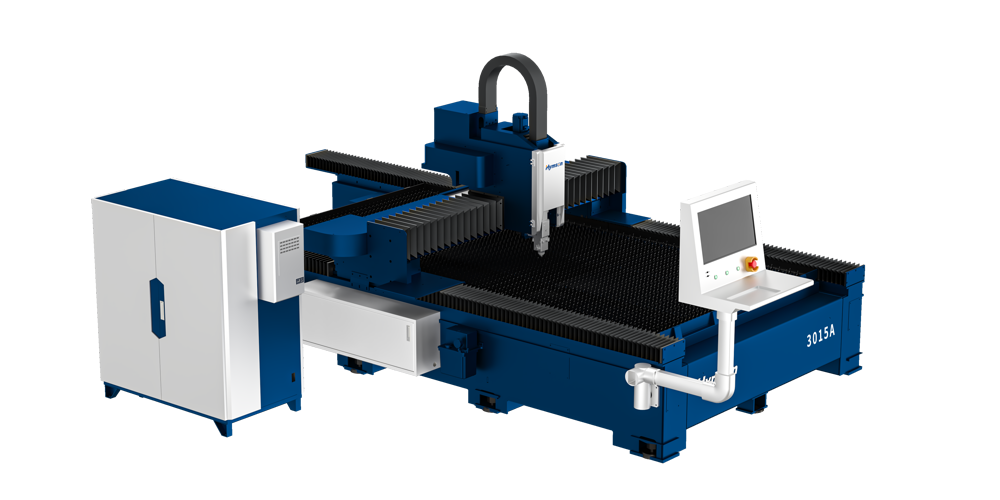

Machine Structure

Machine Structure

Modular Design

- Several components with independent functions are integrated scientifically and systematically for high quality matching of the whole machine.

- With high strength and high reliability of the machine guaranteed, the product development speed is improved to respond to market demand rapidly.

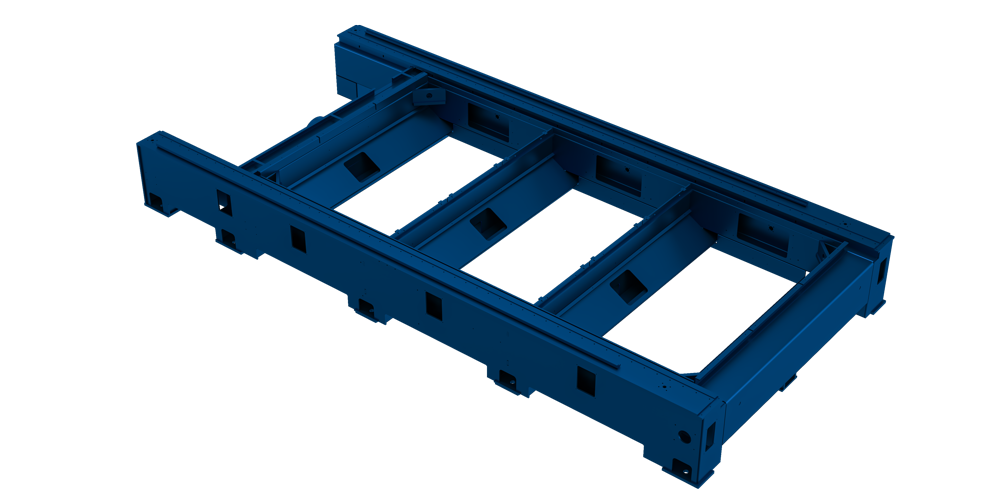

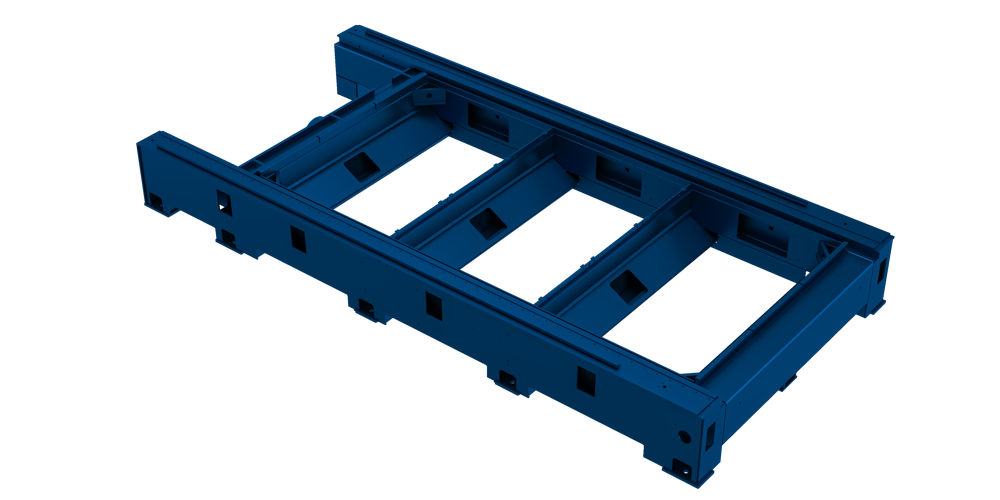

Machine Body with High Strength Structure

- Adopting high strength sheet for welding to guarantee stable structure of the machine and long-time and stable operation of the equipment;

- The machine body processed has undergone high temperature treatment to eliminate internal stress caused by the material itself and welding to the utmost extent, which ensures high strength, high precision and high tolerance.

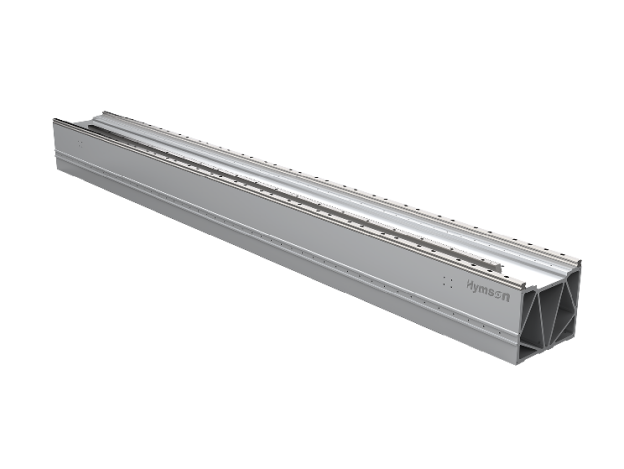

High Strength Cross Beam

- Adopting Hymson’s patented structural design of drawn aluminum cross beam for light overall mass, high tensile strength and superior dynamic performance.

- Through simulated data analysis and testing of different models and lengths, ensuring quality, rigidity and dynamic nature of the cross beam in long-time running.

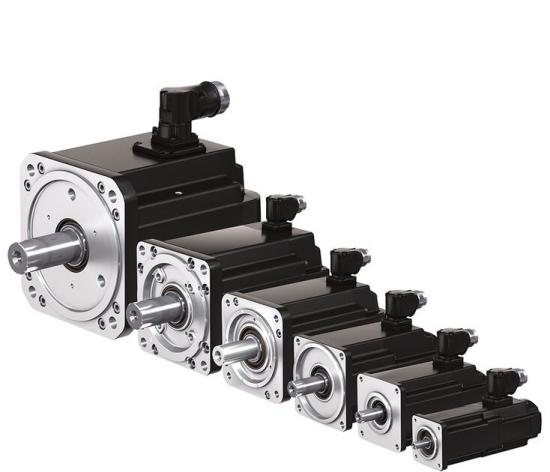

Servo Motor

- Branded servo motor and drive, with high encoder resolution.

- Integrating high dynamics, compact structure and energy efficiency.

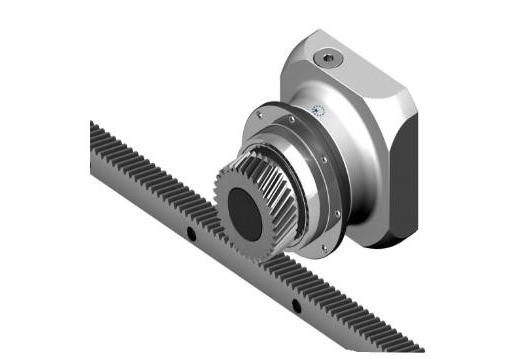

Precision Gear Drive

- ALPHA precision machined high precision pinions and racks having been finished and ground.

- Super high matching rate and precision, high bite rate, smoother and quiet rotation.

- Adopting double drive gantry motion system for higher acceleration and faster movement speed.

- Compact load driven structure for effectively reducing driving torque and eliminating vibration.

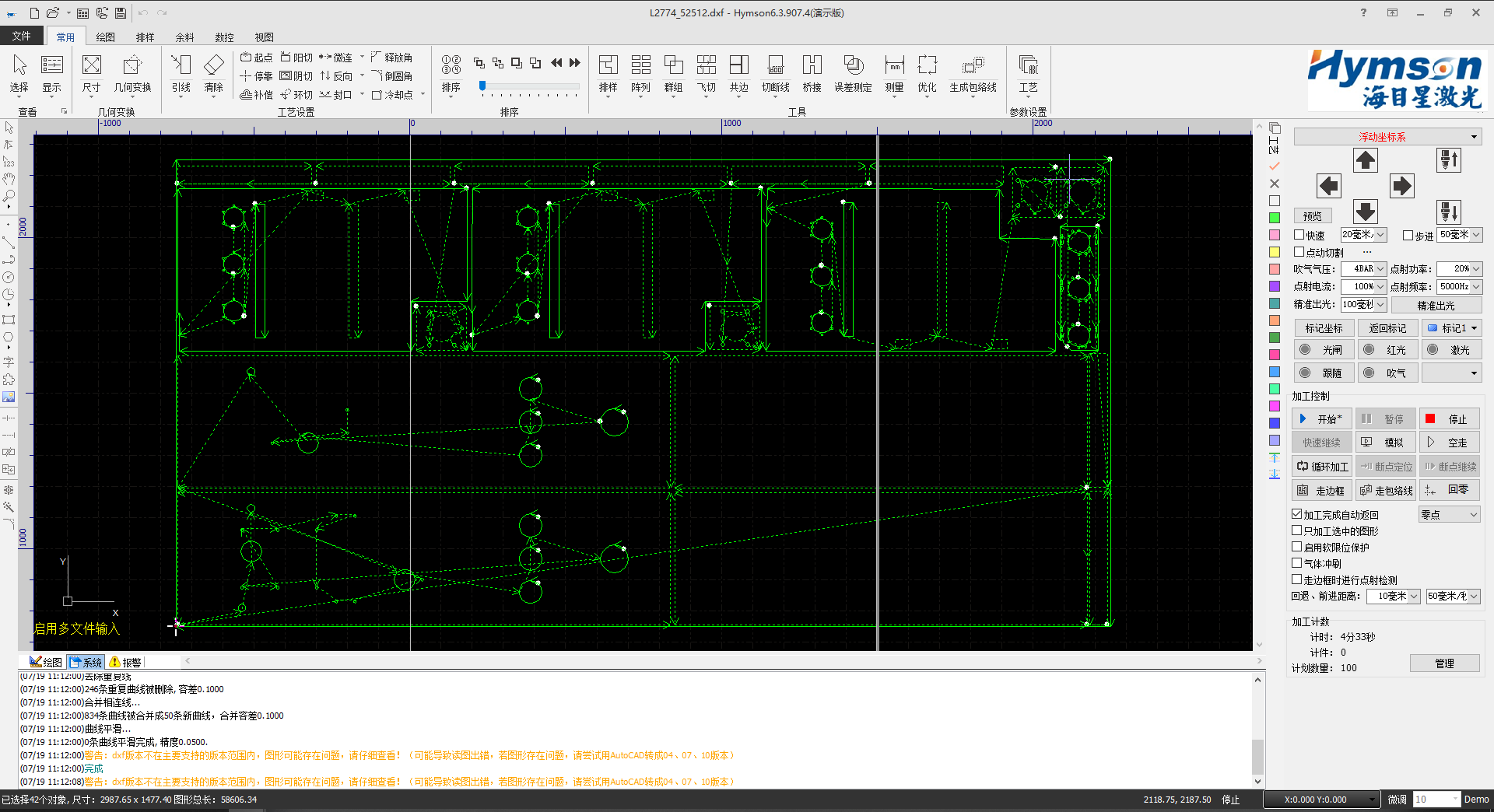

CNC Numerical Control System

- The system is taken as the control platform of a flat laser cutting machine and is developed on the basis of Window 10 architecture. The data calculations are conducted with an industrial grade CPU, which is secure, reliable and self-diagnostics.

- FSCUT, applied to the flat laser cutting system, mainly contains the laser cutting technology processing, common nesting functions and laser processing control. The main functions include the graphic processing, parameter setting, custom cutting process editing, nesting, path planning, simulation, and cutting process control.

- The system can be combined with automatic loading and unloading production lines and flexible production lines of FMS laser cutting to support the automated production.

Performance Indexes

| Equipment Model | HF3015A | HF4020A | HF6020A | HF6025A | HF8025A |

| Effective Cutting Range | 3000mmX1500mm | 4000mmX2000mm | 6000mmX2000mm |

6000mmX2500mm |

8000mmX2500mm |

| X/Y-axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

±0.03mm/m |

±0.03mm/m |

|

X/Y-axis Repositioning Accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

| Maximum Speed of X/Y-axis Linkage Positioning | 110m/min | 110m/min | 110m/min |

100m/min |

100m/min |

| Maximum X/Y-axis Acceleration | 1.2g | 1.0g | 1.0g |

1.0g |

1.0g |

| Floor Space of Whole Machine | 5000mmX2500mm | 6300mmX3000mm | 8300mmx3000mm |

8700mmx3900mm |

10800mmx3900mm |

Let's watch a video of our company

Hymson Laser, founded in 2008, has been making contributions to the fields of laser and automation. Now it has become the world's leading laser and automation equipment integrated solution provider and a national high-tech enterprise.

Aiming at sheet metal applications in different industries, Hymson provides users with professional and high quality product mixes and services, including comprehensive laser automation solutions, such as laser plate cutters, laser tube cutters, laser welding machines, laser automation software, etc.Widely used in engineering machinery, construction machinery, light industrial machinery, agricultural machinery, petroleum machinery, electrical manufacturing, automobile making and aerospace industries.

● Intelligent gas control system: save gas up to 50%

● Auto-focusing: accurate, fast and smart

● Full-automatic lubrication system: Auto lubricate the gear and rack, maintenance free.

● Installation/training & support by global factory trained engineers.

Aiming at sheet metal applications in different industries, Hymson provides users with professional and high quality product mixes and services, including comprehensive laser automation solutions, such as laser plate cutters, laser tube cutters, laser welding machines, laser automation software, etc.Widely used in engineering machinery, construction machinery, light industrial machinery, agricultural machinery, petroleum machinery, electrical manufacturing, automobile making and aerospace industries.

Why choose Hymson laser

● Intelligent dust exhaust system: Work on the cutting area only, strengthen the ventilation effect.● Intelligent gas control system: save gas up to 50%

● Auto-focusing: accurate, fast and smart

● Full-automatic lubrication system: Auto lubricate the gear and rack, maintenance free.

● Installation/training & support by global factory trained engineers.