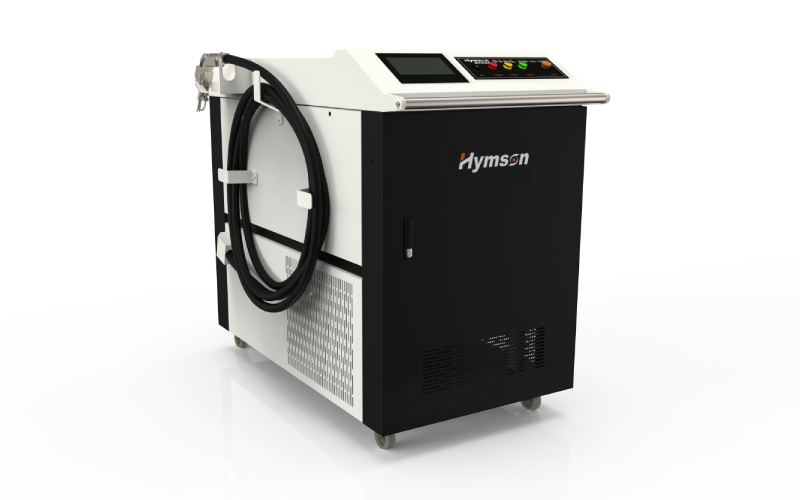

MW Series Handheld Fiber Laser Welding Machine

Application of MW Series Small laser welding machine:

This hand held fiber laser welding machine can be used for Laser welding, precise welding, brass welding, stainless steel welding, etc.

aluminium laser welding machine

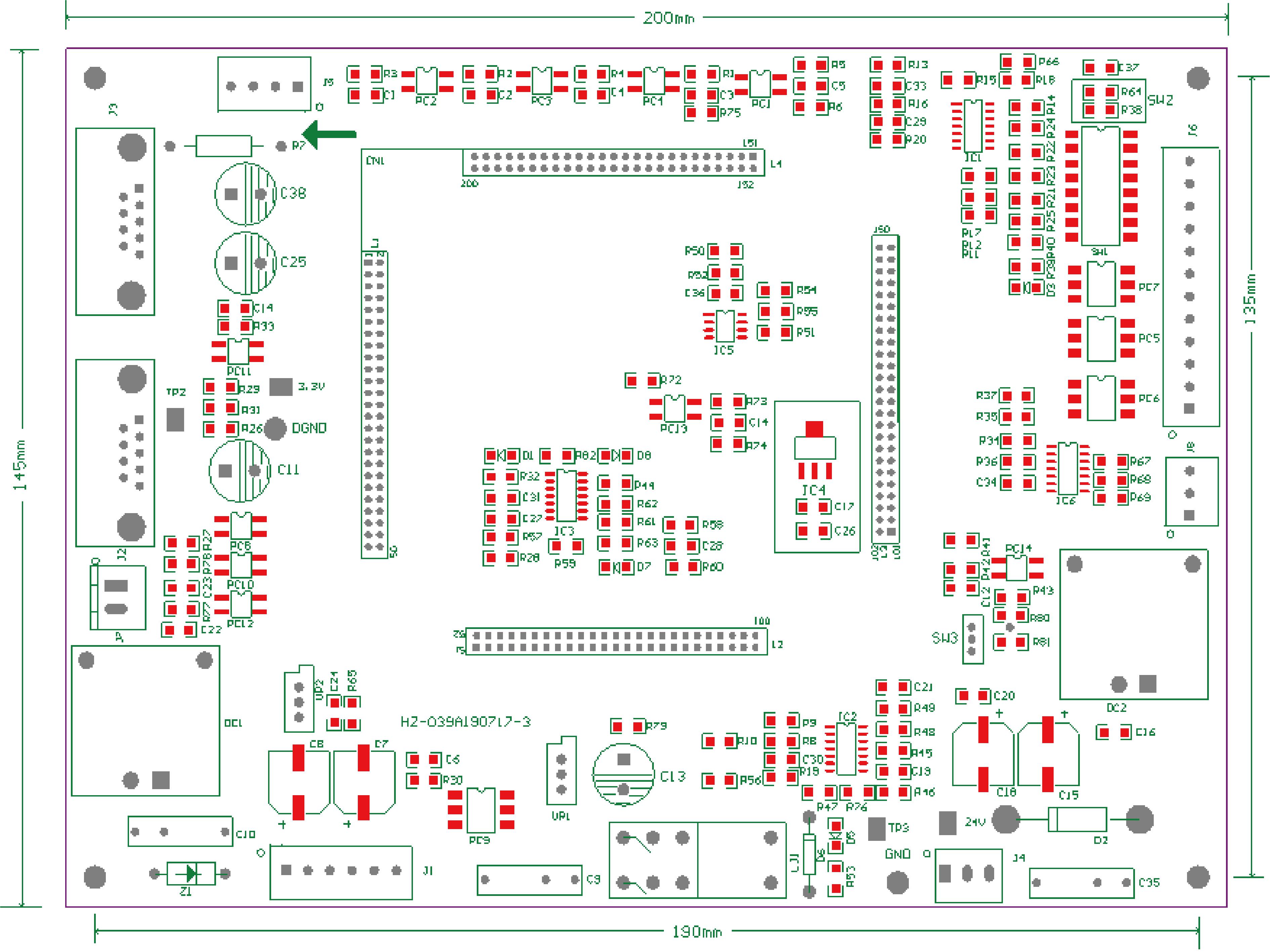

| Working Parameters of Control Card | |

Control Mode |

Pulse |

| Continuous | |

| Modulation | |

| Power Regulating Range of Laser | 10-100% |

| Modulation Frequency | 0-20 KHz |

| Mode of Safety Circuit | Beam emission is stopped once the laser joint is separated from the product |

| Protective Gas | Helium |

| Argon | |

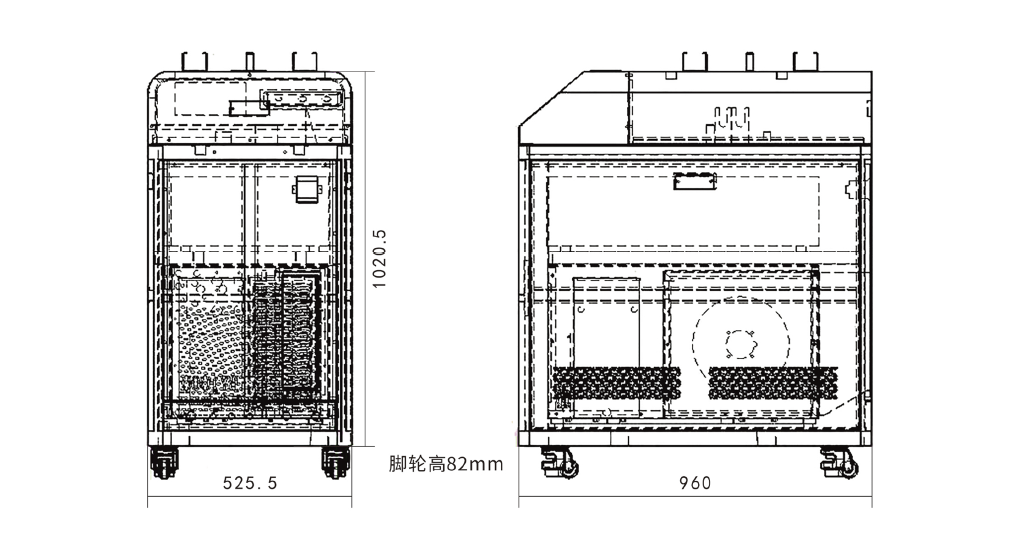

Physical Dimension Drawing (Unit: mm)

Due to the continuous updates of the product, the pictures and technical parameters of the product are for reference only. The material object shall control.

Features of laser Machine Welding:

The Laser Welding Machine adopts optical fiber to transmit high energy density beam. Laser beam emitted through the handheld welding head welds stainless steel, aluminum alloy, etc. It is flexible and convenient to operate.

The Laser Welding Machine is equipped with a single-mode continuous fiber laser and provides high beam quality. It adopts the modular and water-cooling way, with the system highly integrated, with continuously adjustable laser power, and being free from maintenance and highly reliable.

The Laser Welding Machine integrates the fiber laser, handheld welding head, laser control system, safe beam emission system and cooling system. The machine is compact, beautiful and easy to move to allow the customer to be not confined by space when selecting the location and scope of work.

This 1000w laser welding machine can be widely used in the advertising board, metal doorframe, kettle, bathroom accessory and mold repair industries.

Mutiple powers to choose, such as 1000w laser welding machine.

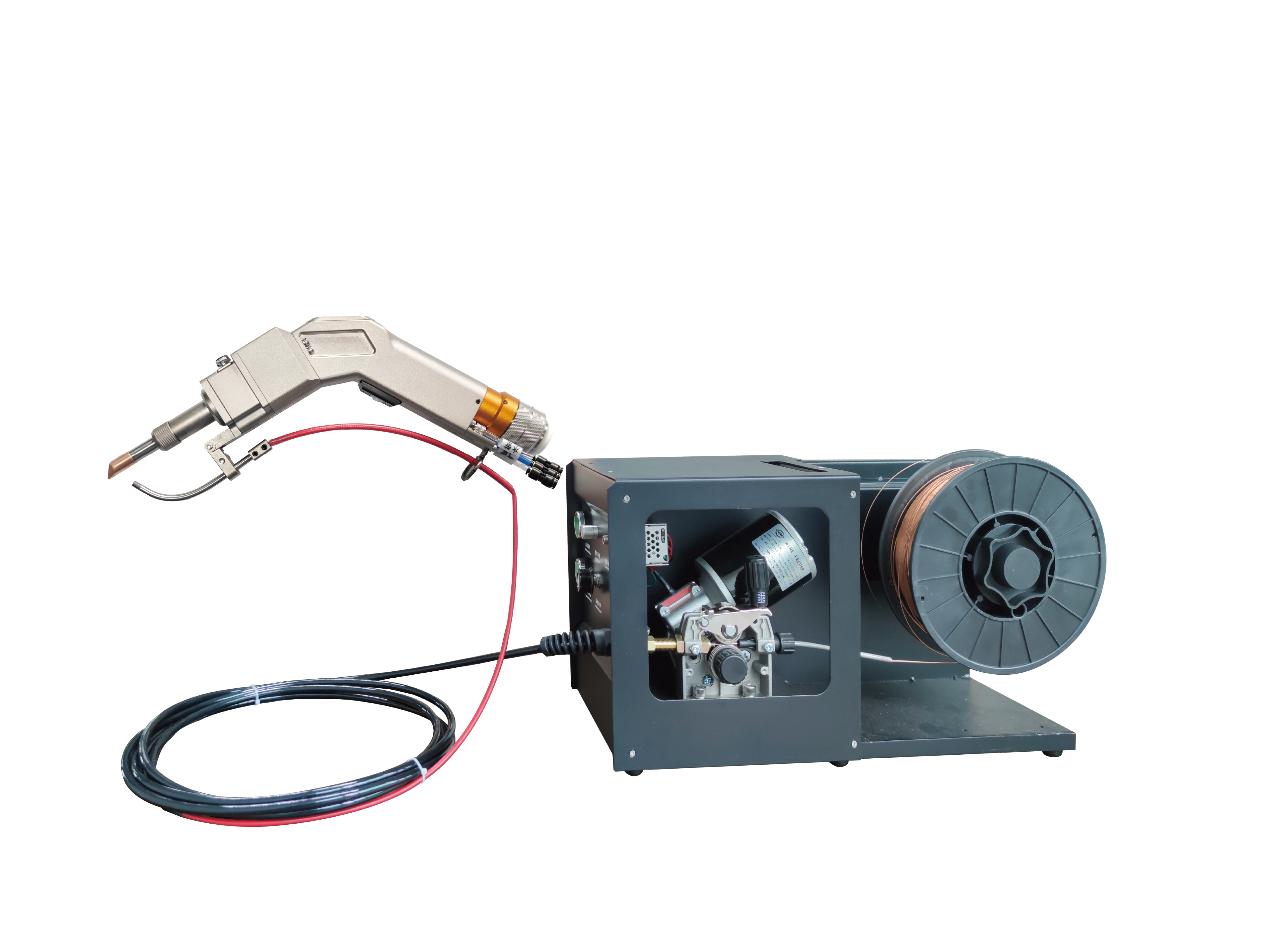

1 .Holding Swing Welding Joint

Customized laser metal welding machine for sale

2. Wire Loading System

high quality laser welding machine for stainless steel

3 .Precision PCB Board

4.Automatic Height Control

The system is equipped with a non-contact capacitive sensor as standard, which ensures a constant distance between the nozzle and the processing material. Even if the workpiece surface is uneven, it has a perfect processing effect.

The automatic height system implements the following functions

Frog lift. When the material burns, the optical head rises to the jump height set by the operator.As the head is raised, the metal melt does not fall on the nozzle part, and cannot be derived or the whole optical head fails. Cut further from the set distance

Cutting on the fly. This method can significantly reduce the processing time of the plate, because it does not cut every detail individually, but cuts all the outlines into a straight line. The high-speed optical head delivers the entire sheet line by line, cutting out the contours of the corresponding segments. It is particularly time-saving to cut the perforated grid.

5. Control Switch of welding machine laser

Including emergency stop, key switch, power switch, etc, convenient to identify, easy to operate.

6.Why choose Hymson laser - One of the laser welding machine suppliers in China

●Intelligent dust exhaust system: Work on the cutting area only, strengthen the ventilation effect.

● Intelligent gas control system: save gas up to 50%

● Auto-focusing: accurate, fast and smart

● Full-automatic lubrication system: Auto lubricate the gear and rack, maintenance free.

● Installation/training & support by global factory trained engineers.

7. This metal laser welding machine adopts optical fiber transmission of high energy density laser, using the light of hand-held welding head to weld stainless steel, aluminum alloy and other materials, it is flexible and convenient for customers to operate.

8. Laser welding machine for aluminum is equipped with single-mode continuous fiber laser, which has hig

h beam quality. What’s more, it adopts modular and water-cooling mode and highly integrated system, free from maintenance and high reliability.

9. The welding machine laser integrates fiber laser, hand-held welding joint, laser control system, safe light extraction system and cooling system. The overall design is compact, beautiful, easy to move, convenient for customers to choose the working place and scope without space limitation.

This set of equipment can be widely used in billboard, metal door frame, kettle, sanitary ware and mold repair and other industries.

| Control | |

| Handheld Control | The remote wireless remote controller allows the operator to perform the most operations from any convenient location: starting and stopping the program, lighting out, following, reversing the contour, increasing/decreasing the focal length, changing the feed rate, and outputting machine parts. |

| Gas Management | |

| Compressor | Screws, air-cooled, with sound-insulated housing, receiver, desiccant, and ancillary equipment for air cutting up to 16 atmospheres. |

| Vertical low-temperature gasifier | Used as a replacement for standard cylinders when used for cutting gas consumption increases. (eg: cutting stainless steel) |

| Safty | |

| Operator safety glasses | Direct, reflected and scattered laser beams may damage the operator's vision and may even lead to blindness. In order to protect the eyes from laser radiation, special protective glasses should be used. |

| Smoke Removal | |

| Exhaust fan | Used to remove the combustion products produced during the cutting process. |

| Filter - Ventilation | Filters - Ventilators are designed to remove suspended, fine and moderately dispersed dust and smoke from air during welding, metal thermal cutting, etc. |

| Spare Parts | |

| Supplies accessories | Protective glasses, nozzle. |

Installation and Commissioning

1. All the equipment provided under the contract should be installed and commissioned by Hymson. After the contract is signed, we will determine the specific installation location of the equipment in the shortest time and provide the equipment foundation drawing within 5 working days after the contract goes into effect. Prior to the installation and commissioning, you should prepare the equipment foundation strictly according to the requirements specified in the equipment foundation drawing provided by Hymson. After the installation site is ensured, the engineers will install and commission the equipment with the tools they carry and, within 10 days, complete the installation, commissioning, technical index tests, training, acceptance and delivery for use;

2. The expenses related to the installation and commissioning and the staff assigned should be borne by Hymson.

Transportation and Logistics

1. The place of delivery should be your installation site.

2. Standard packaging suitable for long-distance transportation by truck, being dampproof, rust-proof and shockproof; suitable for integral hoisting and indicating the centre of gravity for lifting and the hoisting position;

3. Mode of Transport: Motor transport. We should bear the freight and insurance.

4. Each packaging box should be accompanied by a detailed packing list and a quality certification as well as the instructions on the equipment and other documents and materials. The packing list should be outside the packaging box and the quality certification should be inside the packaging box.

Pre-sale Service

1. Welcome to send sample material to us for testing laser marking engraving for you.

2. We offer pictures, videos and other relevant documents for you to know more about the machine.

3. We are online and would respond fast to answer all your questions.

4. If you have chance visiting China, you are warmly welcome to visit our factory.

After-sale Service

1. Any parts have a quality problem during the warranty period, We will send you a new replacement for free. And Customer affords the replacement shipping cost.

2. The training video, detailed manual, and catalog sent with the machine. The customer could study the operation of the machine by watching the clear training video.

3. If there is a technical problem or new inquiry, Hymson has a fast response to service support by online or email even if need by the phone call.

4. Professional technical support and after sales following up. A free software update.

FAQ

1) What are the primary products of your company?

Our primary products include sheet metal laser cutting machine, tube laser cutting machine, precision laser cutting machine, laser welding machine, hand held fiber laser welding machine, manual laser welding machine, laser welding small machine with reasonable fiber laser welding machine price.

2) Where is your fiber laser equipment applied to?

Our hand held fiber laser welding machine is suitable for all kind of stainless steel, carbon steel, aluminium, copper, galvanized steel, electrolytic steel and silicon steel etc.

3) What are the advantages of your laser equipment?

By using Hymson laser, you can monitor end-to-end process and take complete control of all the machining process. The whole machining process will be done smoothly, which will greatly improve production efficiency. In addition, the precision and consistency of the products in mass production is guaranteed.

4) How to do control the quality when you produce laser equipment?

We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser cutting machine. In addition, all raw materials are strictly inspected in accordance with international standards before they are put into production.

5) Which countries are your laser machinery sold to?

Our manual laser welding machine sell all over the world, such as United States, Spain,Netherlands,Poland,France,Turkey, Switzerland,Iran,Egypt, India, South Africa, Malaysia, Canada,Mexico,Colombia,Brazil,Chile,Korea, Japan and many other countries.

| Working Parameters of Whole Machine | |

| Model | NW |

| Power of Fiber Laser | 800 W |

| 1000 W | |

| 1500 W | |

| 2000 W | |

| Wavelength | 1080 nm |

| Beam Quality M2 | 2.8 |

| Short-time Power Stability | ±1% |

| Long-time Power Stability | ±2% |

| Output Fiber Length | 10 m |