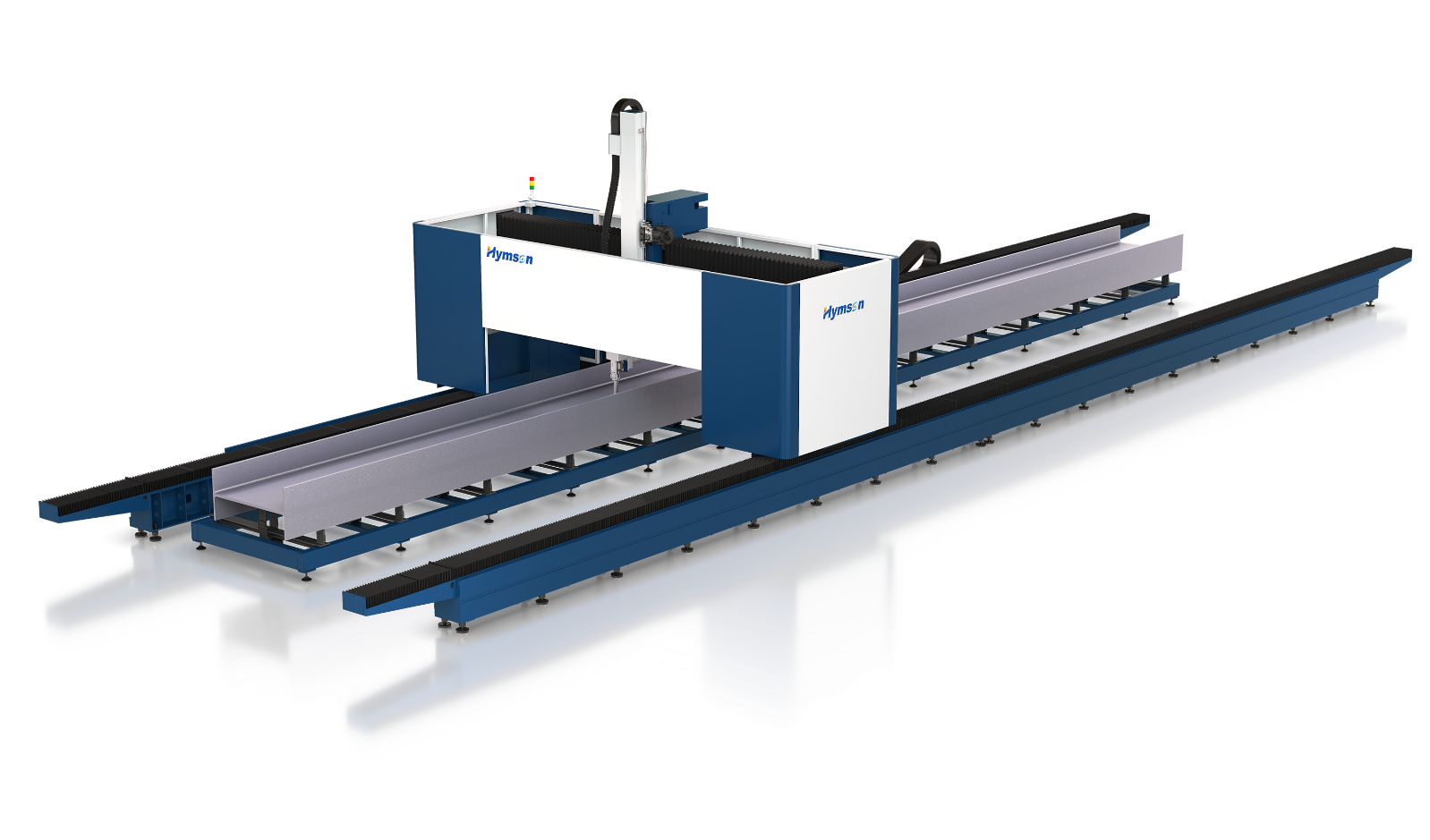

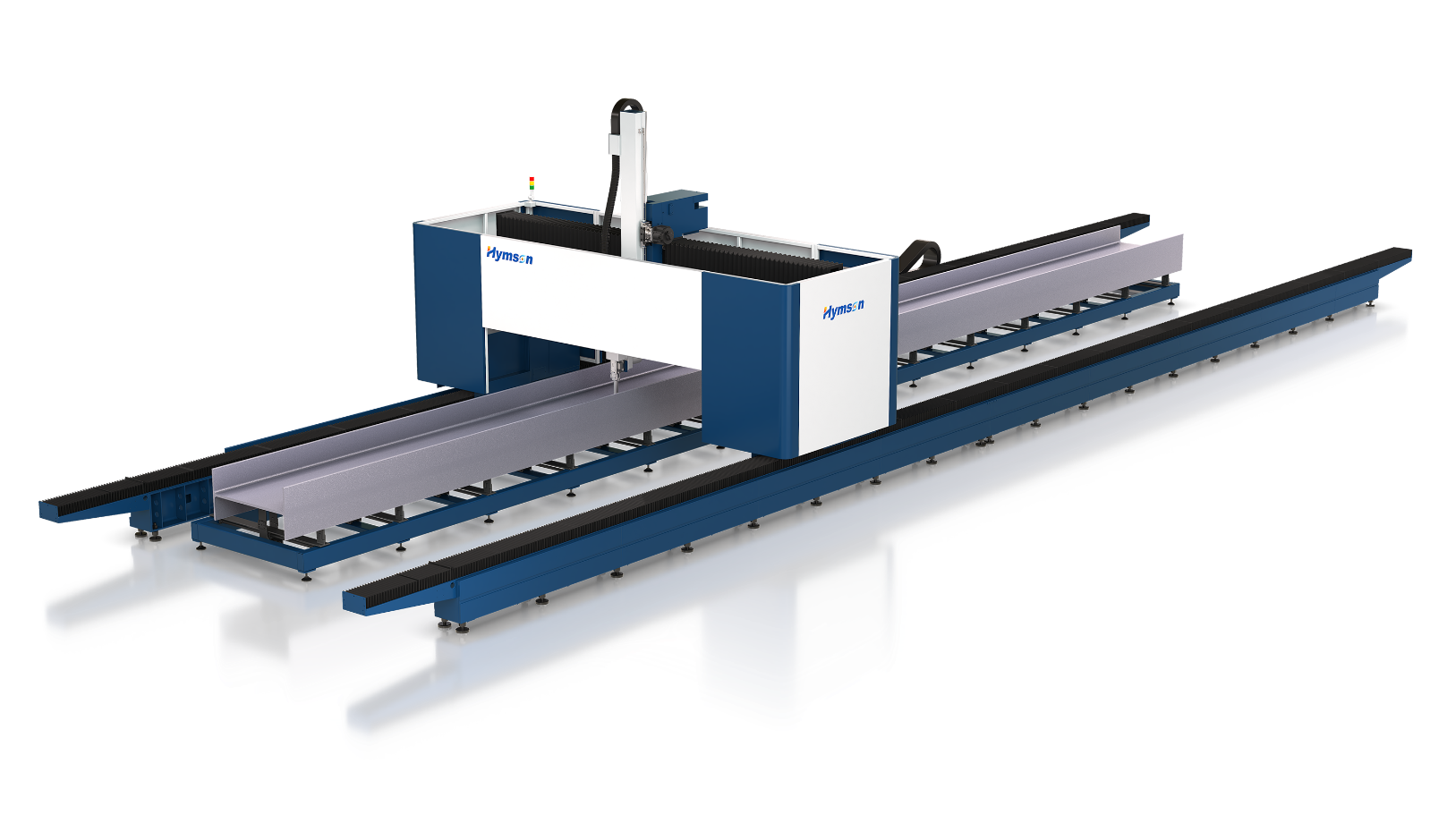

HP30035 SERIES SPECIAL PROFILE LASER CUTTING MACHINE

Hymson HP30035 special cutting machine for profiles is specially produced for steel structures, such as I-beam, HW, HM and HN types of steel, the machine has integrated cutting, punching and grooving functions in one.

Machine Structure

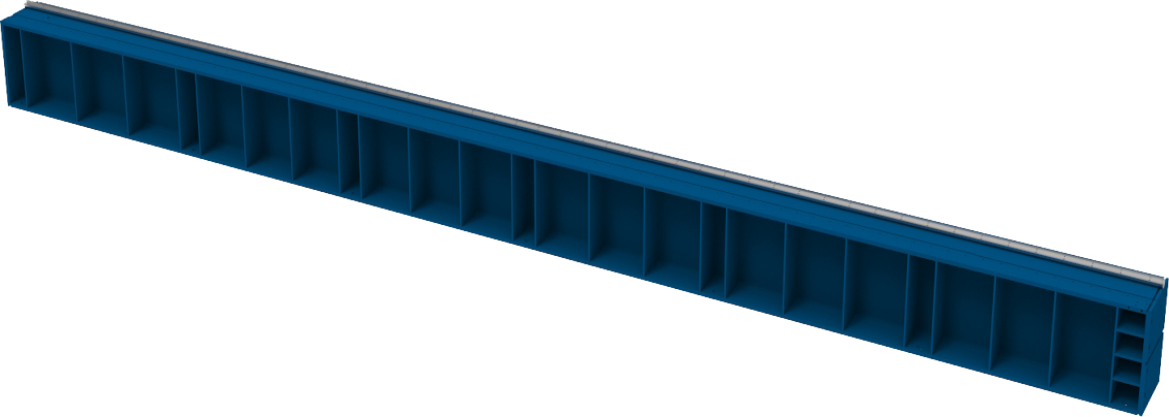

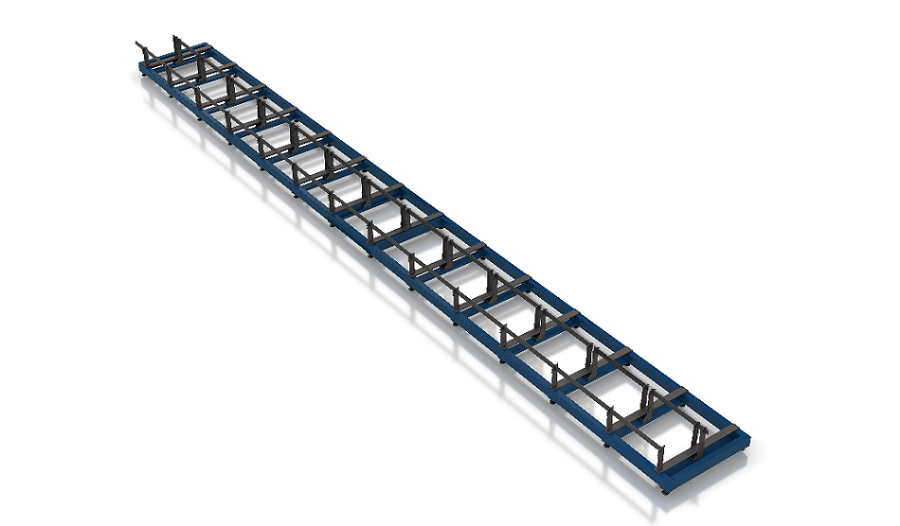

The Machine Body with Splitting Structure

- The machine body is welded with high-strength plates, to ensure that the machine tool has stable structure and it can stably operate for a long time.

- Processing of the machine body adopts high-temperature treatment to maximum eliminate internal stress generated by the material and welding, and ensure high-strength, high-accuracy, and high tolerance.

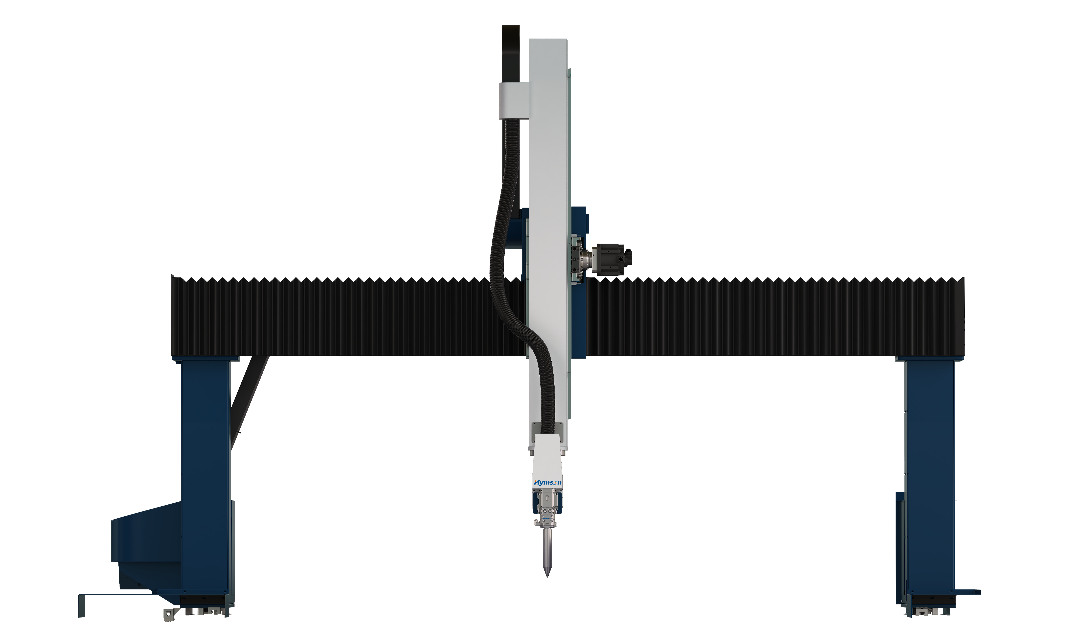

The Beam Structure

- The beam is made of high-intensity steel, which can reduce stress deformation, and ensure stable operation.

Structure of the Cutting Part

- This part adopts high-intensity negative face adjustable support structure, which can be used to cut the material with the width of 200-3000mm.

- The bottom support can be easily adjusted, replaced, the maintenance cost is low.

- The optional composite cutting table can be used to cut flat plates and profiles.

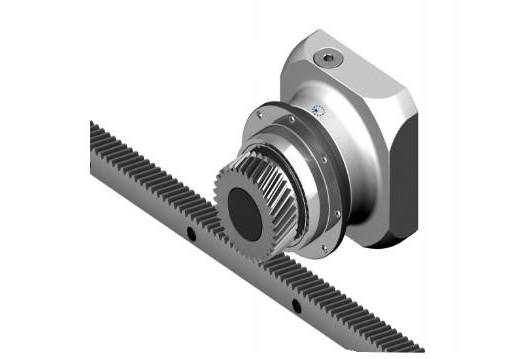

Servo Motor

- The machine adopts brand servo motor and drive, as well as the coder with high resolution.

- High-dynamic and compact appearance, as well as energy efficiency are integrated in one.

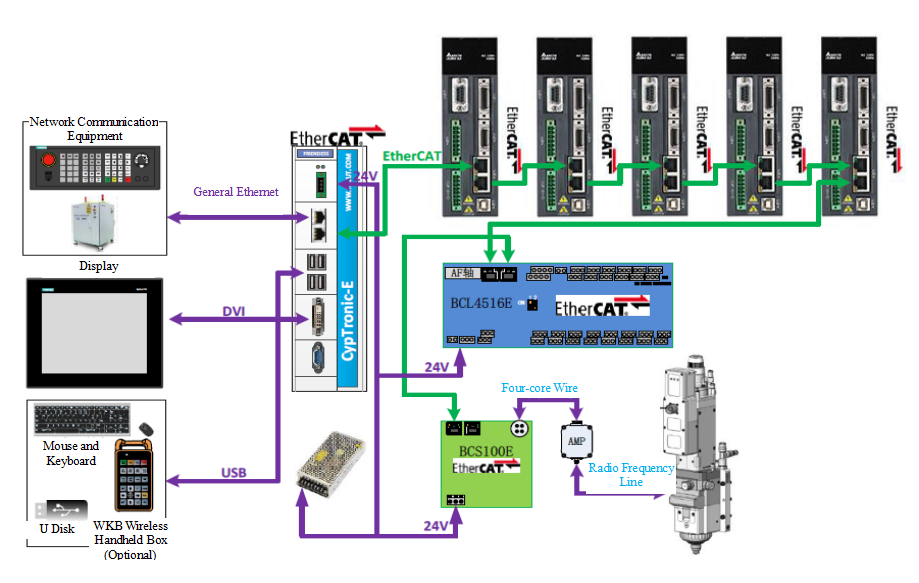

CNC System

FSCUT laser cutting control system is deeply developed based on Windows10 operating system, it adopts Erthercat bus communication mode, integrated modular design, advanced system design architecture, all system software operates on the PC processor.

- Advanced technology: The CNC technical application based on the PC platform already has operation control algorithm experience for many years. All functional modules are opened to users in modular form, without needing any hardware change.

- Excellent performance: The perfect five-axle linkage and coordinate change function can execute complex multi-axle multi-channel coordination control, to meet the application demands of all kinds of CNC equipment. For the profile with slight twist, it can quickly automatically correct and process.

- Perfect functions: The machine can provide abundant function options, execute optimization configuration for application field, to achieve perfect performance.

- Friendly interface: Special real-time CNC core, the real-time CNC difficulties on Windows operating system platform are solved, on the basis of guaranteeing excellent timeliness of the CNC system, it has balanced the system’s features of simple operation and friendly interface.

| Performance Parameters | Main Technical Parameters | |

| Basic Parameters | Power of the Laser | 20000W |

| CNC System | FSCUT | |

| Processing Type | H-steel, U-steel, angle steel and flat plate etc. | |

| Function | Segment cutting, cutting of wing plate and web, groove cutting and marking | |

| Linkage Axles | Five axles(X/Y/Z/A/B) | |

| Nesting Software for Profile Steel | Friendness nesting software for profile steel; Compatible with 3D software, such as Tekla, SW, and CAD etc; | |

| Processing Capacity | Sectional Dimensions of the Profiles to be Processed | Web H≤1200mm |

| Flange B≤600mm | ||

| Length L≤12000mm | ||

| Cutting Thickness(Carbon Steel O2) | Vertical cutting MAX:20mm; groove cutting MAX:30mm | |

| Groove Cutting Range | 0-45° groove | |

| Processing Speed | X,Y Axles Maximum Positioning Speed | 40m/min |

| Acceleration | X,Y Axles Maximum Acceleration | 0.6g |

| Positioning Accuracy | X, Y Axles Positioning Accuracy | 0.05mm/10m(≤10m时),0.1mm/whole length |

| Specification(Covering an Area) | Dimensions of the Machine | 35m x 5m x 4.5m |