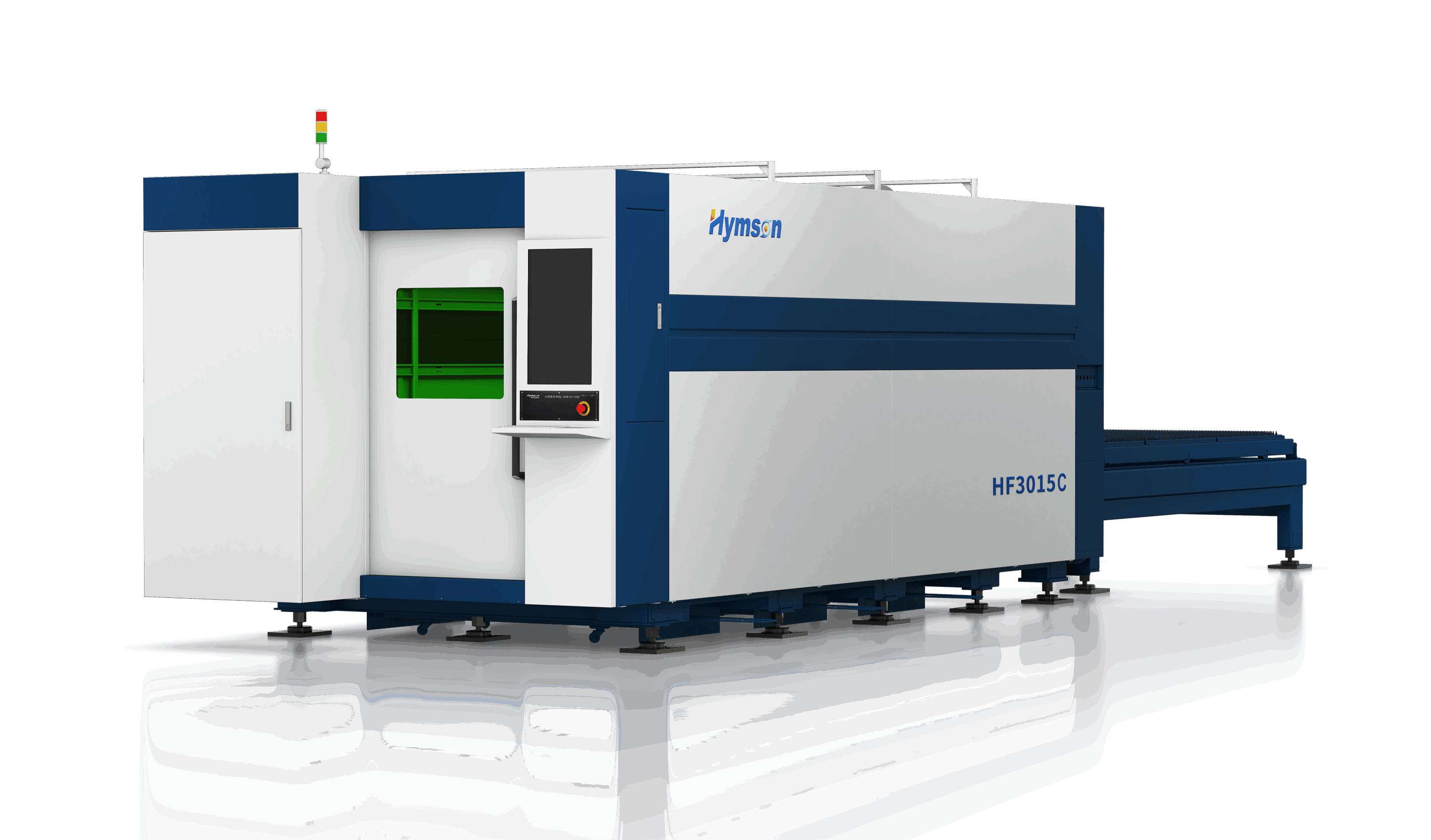

As modern manufacturing pushes for greater productivity and flexibility, laser cutting has become a cornerstone technology in sheet metal fabrication. Hymson’s HF-C Series Fiber Laser Cutting Machine is engineered to deliver unmatched speed, accuracy, and automation. Combining high-performance hardware with intelligent controls and scalable platform options, the HF-C Series is built for businesses looking to embrace smart manufacturing at all scales.

Whether you are a distributor serving industrial clients or an application engineer designing custom production lines, the HF-C Series delivers value through modular design, reliable core technology, and end-to-end service.

Contents:

Making Laser Cutting More Accessible and Scalable

Beyond Hardware ---A Testament to Hymson’s Technological Strength

Powering Global Manufacturing with Scalable, Smart Solutions

Making Laser Cutting More Accessible and Scalable

Developed as part of Hymson’s high-efficiency sheet metal product line, the HF-C Series offers tailored configurations for both established operations and first-time laser adopters.

Key Advantages:

|

Feature |

HF·C Series Value |

|

Power Range |

3kW – 20kW – Adaptable for thin to ultra-thick metal cutting tasks |

|

Compact Gantry Structure |

Space-efficient design with welded bed and gantry-mounted drive ensures high rigidity and lower vibration |

|

Integrated Automation |

Optional modules like auto-loading/unloading systems increase automation with minimal operator intervention |

|

Energy Efficiency |

Fiber laser technology reduces consumption and operating costs compared to CO₂ laser counterparts |

|

First-Timer Friendly |

Highly intuitive control software supports fast onboarding and parameter customization for new users |

Because the system supports multiple material types (carbon steel, stainless steel, aluminum alloy and brass), it opens up applications not just for mass producers but also for SMEs looking to digitize their factories.

Beyond Hardware—A Testament to Hymson’s Technological Strength

The HF-C Series doesn’t just offer robust mechanics; it leverages Hymson’s proprietary ecosystem of software and hardware for class-leading performance.

Core Technology:

- Self-Developed Control System---Seamless bus control technology optimizes laser, motion and safety interlocking.

- Hymson Laser Head—Integrates anti-collision, autofocus and real-time monitoring features for longevity and precision.

- Intelligent Parameter Matching---Built-in library of cutting parameters ensures optimized speed and energy usage per material and thickness.

- Rapid Commissioning---Pre-calibrated modules enable faster installation and transition to production.

- Open Design for Maintenance—Easy-access layout supports efficient maintenance and component swaps, minimizing downtime.

These features collectively reduce the learning curve, enhance system reliability, and shorten time-to-market—critical factors for distributors managing multiple client types and engineering teams working against tight deadlines.

Powering Global Manufacturing with Scalable, Smart Solutions

The HF-C Series sits at the core of Hymson’s scalable automation platform, which includes:

- Intelligent Nesting Software

- Modular Loading/Unloading Devices

- ERP/MES Data Docking

- Remote Diagnostic Tools

This flexibility empowers system integrators and manufacturers to tailor solutions for varying output needs—from one-off precision jobs to full-volume automated lines. In industries such as automotive parts, kitchenware, elevator shafts, and electric cabinets, the HF-C Series helps reduce cycle times while delivering a consistent high-quality edge finish.

Hymson’s global footprint ensures that distributors can offer competitive lead times, localized service, and performance reliability.

About Hymson

Founded in Shenzhen, China, Hymson Laser is a leading provider of industrial laser equipment and smart automation solutions. With R&D and production bases in Jiangmen, Anshan, and Suzhou—as well as subsidiaries in Italy, the USA, and Korea—Hymson offers end-to-end support to over 3,000 customers worldwide.

Core Capabilities:

- Full-line solutions: From flatbed cutting to 3D laser processing and welding

- In-house product ecosystem: Control systems, cutting heads, software—fully engineered by Hymson

- Global support network: Fast installation, parts availability, and after-sales service

Backed by a strong engineering team and thousands of machines in the field, Hymson is the reliable choice for distributors seeking scalable, intelligent laser solutions.

Frequently Asked Questions

Q1: What materials can the HF-C Series cut?

A1: It can cut carbon steel, stainless steel, aluminum, brass, and galvanized steel with thicknesses of up to 40mm depending on the laser power.

Q2: Is the HF-C Series suitable for automation?

A2: Absolutely. It supports peripheral automation modules like robotic arms, CCD cameras, and MES integration.

Q3: How long does it take to install and commission?

A3: Typical installation time is 5–10 days depending on configuration, significantly faster with Hymson’s pre-tested components.

Q4: Is technical support available in North America?

A4: Yes, Hymson maintains service centers and engineers in the USA and offers fast spare parts availability.

Share This Post: