In the fast-evolving landscape of modern manufacturing, the pursuit of precision, speed, and efficiency is relentless. Sheet metal fabrication, a cornerstone of industries ranging from aerospace to consumer electronics, has been revolutionized by technological advancements. Among these, laser cutting technology stands out as a transformative force. Choosing the right sheet metal laser cutting machine is no longer just a procurement decision; it is a strategic investment that can define a company's competitive edge, production capacity, and product quality for years to come.

This guide will provide a deep dive into the world of sheet metal laser cutting, covering everything from fundamental principles and key components to market trends and common purchasing pitfalls. Our goal is to empower you with the knowledge to make a rational, informed decision that aligns perfectly with your operational needs and business objectives.

Technological Innovation and an Overview of Sheet Metal Laser Cutting Machines

The journey of laser technology from a laboratory curiosity to an industrial workhorse is a testament to relentless innovation. Today, its application in sheet metal cutting represents the pinnacle of fabrication technology, offering capabilities that were once unimaginable.

The Importance of Sheet Metal Laser Technology Before the advent of laser cutters, sheet metal processing relied on mechanical methods like punching, shearing, and plasma cutting. While effective, these methods have inherent limitations. Mechanical punching requires expensive custom dies for each new design, making prototyping and small-batch production costly and slow. Plasma cutting, while powerful, often struggles with precision and can create a large heat-affected zone (HAZ), requiring secondary finishing processes.

Laser cutting overcomes these challenges. It is a non-contact, thermal process that uses a highly focused, high-energy beam of light to melt, vaporize, or burn through material with exceptional accuracy. This tool-less process means design changes can be implemented instantly through software, offering unparalleled flexibility and dramatically reducing lead times.

The Advantages of High Precision and High Speed The two defining characteristics of modern laser cutting are its precision and speed.

- Precision: A modern fiber laser cutter can achieve positional accuracy of ±0.02mm . This allows for the creation of incredibly intricate parts with fine details and sharp corners, all with minimal material wastage. The narrow kerf (the width of the cut) ensures that components fit together perfectly, which is critical for assembly-line production and high-performance applications.

- Speed: For thin to medium-thickness metals, laser cutting is exceptionally fast. High-power lasers can slice through thin stainless steel at speeds exceeding 60 meters per minute. This high throughput translates directly into increased productivity and lower per-part costs, enabling businesses to take on larger orders and meet tighter deadlines.

Basic Principles and Applications At its core, a laser cutting machine operates on a simple principle. A laser source, known as a resonator, generates a powerful beam of light. This beam is directed through a series of mirrors or a fiber optic cable to a cutting head. Inside the head, a lens focuses the beam onto a tiny spot on the surface of the sheet metal. The intense energy concentration at this focal point melts the material. Simultaneously, a jet of assist gas (such as nitrogen, oxygen, or compressed air) is directed through a nozzle coaxial with the laser beam. This gas jet blows the molten material away, creating a clean cut.

The entire process is controlled by a Computer Numerical Control (CNC) system, which reads a digital design file (e.g., a DXF or DWG file) and precisely moves the cutting head over the metal sheet to execute the desired pattern. This automation ensures perfect repeatability and allows for the production of complex geometries that would be impossible with manual methods. Its applications are vast, spanning automotive body panels, aerospace components, structural steel for construction, intricate medical devices, and even decorative metalwork.

The Sheet Metal Laser Cutting Process and Its Application Fields

Understanding the nuances of the laser cutting process and its distinction from similar technologies is crucial for appreciating its wide-ranging utility across various industries.

How Sheet Metal Laser Cutting Works The cutting process can be broken down into three main types, depending on the material and the assist gas used:

- Fusion Cutting (Melt Shearing): This is the most common method for cutting stainless steel, aluminum, and other non-ferrous alloys. An inert gas, typically nitrogen, is used as the assist gas. The laser beam melts the metal, and the high-pressure nitrogen jet blows the molten material out of the kerf. Because nitrogen does not react with the molten metal, it produces a smooth, oxide-free, silver-bright cutting edge that is ready for welding without further processing.

- Oxidation Cutting (Flame Cutting): This method is primarily used for mild steel (carbon steel). Oxygen is used as the assist gas. The laser beam heats the material to its ignition temperature, and the oxygen jet initiates an exothermic reaction (burning), which provides additional energy to the cutting process. This allows for cutting thicker materials at higher speeds compared to fusion cutting. However, it leaves a thin oxide layer on the cut edge, which may need to be removed before painting or welding.

- Sublimation Cutting: Used for certain non-metals like wood or acrylics, this process involves the laser beam vaporizing the material directly from a solid to a gas state, leaving a very clean edge. This is less common in sheet metal work.

Distinguishing Laser Cutting from Engraving While often performed by the same machine, cutting and engraving are fundamentally different processes with different purposes.

- Laser Cutting: The objective is to penetrate completely through the material to separate one piece from another. This requires high power and a carefully controlled speed to ensure a full-depth cut.

- Laser Engraving/Marking: The objective is to alter the surface of the material without cutting through it. This is achieved by using lower power or much higher speeds. Engraving removes a small amount of material to create a mark with depth, while marking often uses heat to cause a surface discoloration (annealing) or a slight chemical change, resulting in a permanent, high-contrast mark with no material removal.

Applications of Laser Cutting Technology Across Industries The versatility of laser cutting has made it indispensable in numerous sectors:

- Automotive: For prototyping and mass production of chassis parts, body panels, frame components, and exhaust systems. The precision ensures perfect fit and finish.

- Aerospace: For cutting high-strength, lightweight alloys like titanium and aluminum composites for fuselage components, brackets, and engine parts where accuracy and structural integrity are paramount.

- Electronics: For manufacturing intricate enclosures, chassis, and mounting plates for servers, consumer devices, and control panels.

- Medical Devices: For creating highly precise surgical instruments, implants (like stents), and components for diagnostic equipment from medical-grade stainless steel and titanium.

- Heavy Machinery & Construction: For cutting thick steel plates for structural components, agricultural equipment, and construction machinery.

- Furniture & Design: For creating bespoke metal furniture, decorative panels, and architectural elements with complex, artistic patterns.

Technical Specifications and Key Components

The performance of a laser cutting machine is defined by its technical specifications and the quality of its core components. Understanding these elements is key to evaluating and comparing different models.

Laser Beam Specifications

- Power (kW): This is perhaps the most critical specification. It directly determines the maximum thickness of material you can cut and the speed at which you can cut it. Power ranges from 1 kW for thin sheet metal to over 30 kW for heavy plate cutting.

- Wavelength (µm): The wavelength of the laser light determines how well its energy is absorbed by different materials. Fiber lasers typically operate at a wavelength of ~1.06 µm, which is highly absorbed by metals, making them extremely efficient. CO2 lasers operate at ~10.6 µm, which is better absorbed by organic materials and non-metals.

- Beam Quality (M²): This measures how tightly the laser beam can be focused. A lower M² value indicates higher beam quality, allowing for a smaller focal spot, higher power density, and a finer, more precise cut. Fiber lasers generally have superior beam quality compared to CO2 lasers.

The Laser Resonator (Laser Source) The resonator is the heart of the machine, responsible for generating the laser beam. The two dominant types in the sheet metal industry are:

- Fiber Laser Resonator: This solid-state laser uses semiconductor diodes to pump light into an optical fiber that is doped with a rare-earth element like ytterbium. The light is amplified within the fiber, generating the laser beam.

- Working Principle: Light is generated and amplified entirely within a flexible fiber optic cable, eliminating the need for complex mirrors or gas cavities.

- Advantages: Extremely high energy efficiency (~30-40%), no moving parts in the source, minimal maintenance, long service life (>100,000 hours), and excellent beam quality.

- CO2 Laser Resonator: This gas laser uses an electrical discharge to excite a mixture of gases (primarily carbon dioxide, nitrogen, and helium) within a sealed tube or cavity, causing it to lase.

- Working Principle: High voltage is passed through the gas mixture, and a system of mirrors reflects the light back and forth to amplify it before it is emitted.

- Advantages: Excellent cut quality on a very wide range of materials, including non-metals. Still preferred for thick-section acrylic cutting.

The Cutting Head The cutting head is the "business end" of the machine. It takes the laser beam from the source and delivers it to the workpiece. Its key components include:

- Focusing Lens/Mirrors: These optics focus the laser beam to a precise point, concentrating its energy.

- Nozzle: This directs the assist gas onto the workpiece, clearing the molten material. The nozzle's diameter and design are critical for cut quality.

- Capacitive Height Sensor: This sensor constantly measures the distance between the nozzle and the metal sheet, automatically adjusting the head's Z-axis position to maintain a perfect focal distance, even if the sheet is slightly warped.

- Modern Features: Advanced cutting heads now include auto-focus capabilities, collision detection, and even integrated beveling functions that allow for angled cuts (e.g., for weld preparation) in a single pass.

Key Factors Influencing Cutting Quality Achieving a perfect cut is a balance of several factors:

- Cutting Speed: Too fast, and the beam won't penetrate fully, leaving dross. Too slow, and excessive heat input can widen the kerf and create a larger HAZ.

- Laser Power: Must be appropriate for the material type and thickness.

- Assist Gas: The type (N2, O2, Air) and pressure must be optimized. Incorrect pressure can lead to burrs or a rough edge.

- Focal Position: The position of the focal point relative to the material surface (above, at, or below the surface) significantly impacts edge quality and kerf width.

Differentiating Types of Laser Cutting and Engraving Machines

While the underlying technology is similar, laser machines are often specialized for cutting, engraving, or both. The primary distinction comes from the type of laser source used.

Defining Marking, Engraving, and Cutting

- Marking: A surface-level process that changes the color of the material through annealing or chemical alteration. It creates no depth.

- Engraving: A process that removes material from the surface to create a visible, tactile depression. The depth can be controlled by power and speed.

- Cutting: A full-depth process that separates the material into two or more pieces.

Main Types of Laser Cutting Machines

Fiber Laser Cutting Machines

Principle: Uses a solid-state fiber laser source. The beam is delivered via a flexible fiber optic cable.

Applicable Materials: Primarily metals. Exceptionally effective on steel, stainless steel, aluminum, brass, copper, and other alloys. Very poor for most organic materials like wood or clear acrylic.

Pros:

Very high cutting speed on thin to medium metals.

Extremely high electrical efficiency, leading to lower operating costs.

No maintenance required for the laser source (no mirrors to align, no gas to refill).

Can easily process reflective materials like brass and copper.

Cons:

Higher initial investment compared to CO2 lasers of similar power.

Not suitable for cutting non-metals.

CO2 Laser Cutting Machines

Principle: Uses a gas-based laser source. The beam is delivered via a system of mirrors (a "flying optics" system).

Applicable Materials: Highly versatile. Cuts a vast range of non-metals (wood, acrylic, leather, fabric, paper, rubber) and can also cut metals (though less efficiently than fiber lasers).

Pros:

Excellent versatility for businesses working with diverse materials.

Produces a superior, flame-polished edge on acrylics.

Lower initial cost for the machine itself.

Cons:

Much lower electrical efficiency, leading to higher energy bills.

Requires regular maintenance (mirror alignment, gas refills, optics cleaning).

Slower cutting speeds on metals compared to a fiber laser of equivalent power.

The beam path with mirrors is sensitive to misalignment.

Crystal Laser Cutting Machines (e.g., Nd:YAG, Nd:YVO)

These are also solid-state lasers but use a crystal as the lasing medium. They have largely been superseded by fiber lasers in the sheet metal cutting industry due to the superior efficiency and reliability of fiber technology. They are still used in specialized applications like high-precision marking, welding, and cutting of both metals and some plastics/ceramics.

Market Price Trends and Product Recommendation

The price of a laser cutting machine can vary dramatically based on its type, power, size, brand, and features.

Price Ranges for Different Types of Sheet Metal Laser Cutters

- Entry-Level / Small Business (1kW - 3kW): These are typically fiber laser machines suitable for cutting thin sheet metal (up to ~6mm steel) for job shops, sign makers, and light fabrication.

- Industrial Mid-Range (3kW - 6kW):This is the sweet spot for many fabrication shops, offering a good balance of speed and thickness capability (up to ~20mm steel).

- High-Power Industrial (8kW - 20kW+): $These machines are built for heavy-duty, high-volume production, capable of cutting thick plates quickly. They often come with automation features.

- Automated Systems (with loading/unloading towers): These systems allow for 24/7 "lights-out" operation.

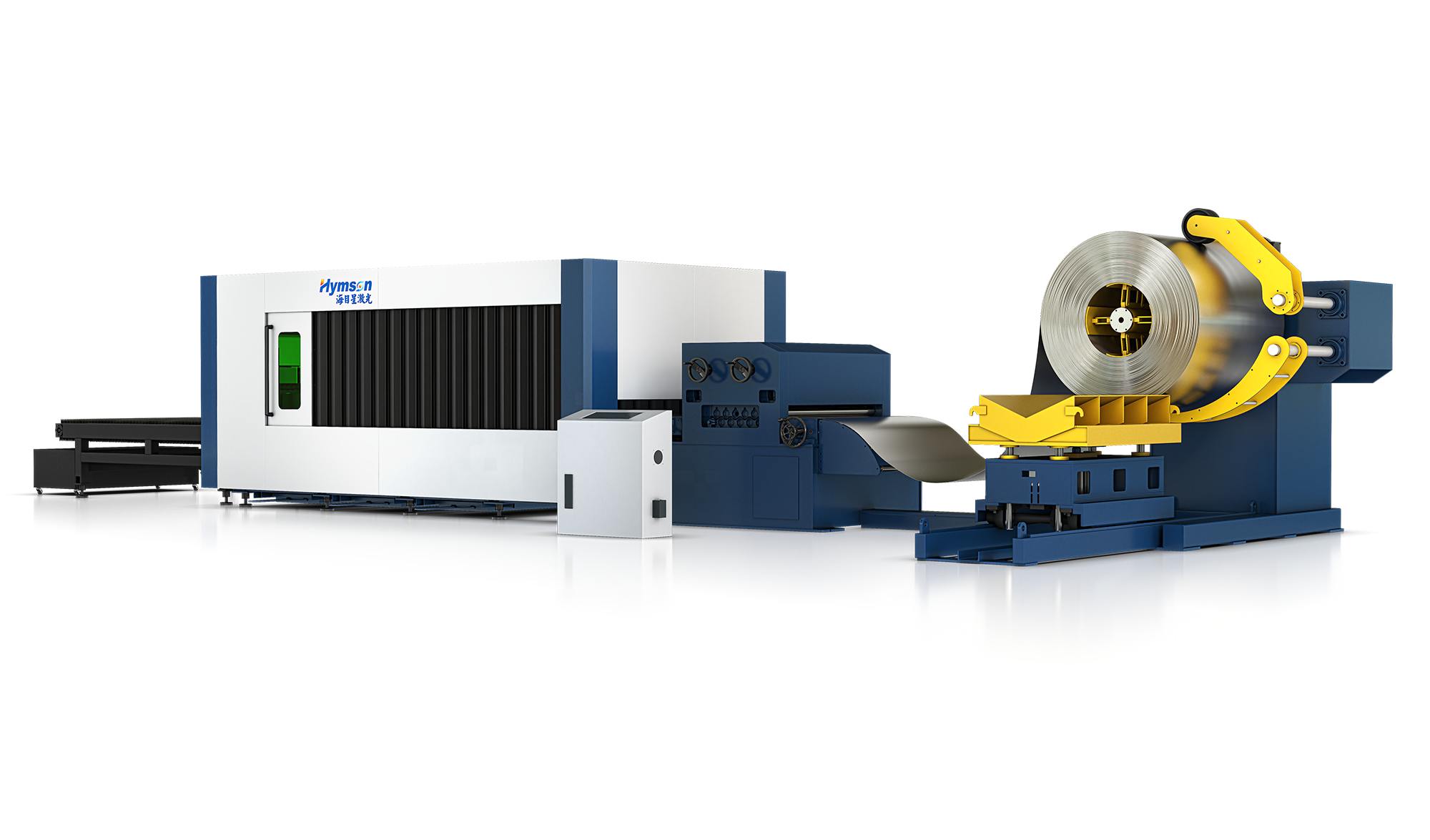

Industry-Grade Recommendation: Hymson HF-TU Series Fiber Laser Cutting Machine

For businesses seeking a state-of-the-art, versatile, and highly productive solution, a machine like the Hymson HF-TU Series serves as an excellent benchmark for what modern technology offers. It is a prime example of an integrated plate and tube laser cutting machine designed for demanding industrial environments.

Key Features and Application Scenarios:

- Integrated Plate and Tube Cutting: This is a major advantage, combining two machines into one. It allows a business to cut standard sheet metal and also process round, square, rectangular, and other profile tubes. This versatility opens up new markets, such as furniture manufacturing, fitness equipment, and structural framework.

- High Power Options (up to 6,000W+): With power options ranging from 3kW to over 6kW, the HF-TU series can be configured for any task, from rapidly cutting thin sheets to powerfully slicing through thick steel plates (e.g., 50mm+).

- Advanced Bevel Cutting Head: The machine can be equipped with a 3D five-axis cutting head capable of performing ±45° bevel cuts. This is a game-changer for weld preparation, as it eliminates the need for a secondary grinding or milling process, saving significant time and labor.

- Intelligent Bus Control System: Modern systems like Hymson's EtherCAT bus control system. This provides faster communication between the CNC and the machine components, resulting in higher acceleration, better accuracy, and more sophisticated real-time monitoring and diagnostics.

- Full Automation Options: The HF-TU series can be integrated with fully automatic loading and unloading systems. This creates a production cell that can run continuously with minimal operator intervention, maximizing throughput and reducing labor costs.

Common Pitfalls in the Selection Process

Choosing a laser cutter is a significant investment, and several common mistakes can lead to buyer's remorse.

- Pitfall 1: Focusing Solely on Initial Price: The cheapest machine is rarely the best value. Consider the Total Cost of Ownership (TCO), which includes energy consumption, consumables (nozzles, lenses), maintenance costs, and potential downtime. A more efficient, reliable machine with a higher upfront cost can be cheaper in the long run.

- Pitfall 2: Incorrect Power Specification: Buying a machine that is either too powerful or not powerful enough is a costly error. A 20kW laser to cut 1mm sheet is inefficient and wasteful. A 1.5kW laser will be unable to handle a sudden need to cut 15mm plate. Analyze your current and near-future workload (the 80/20 rule applies – spec for 80% of your work) to find the right power level.

- Pitfall 3: Overlooking Software and Workflow Integration: The machine is only one part of the equation. How intuitive is the CAD/CAM software? How easily does it integrate with your existing design and ERP systems? Poor software can create a production bottleneck that negates the speed of the machine itself.

- Pitfall 4: Neglecting After-Sales Service and Support: This is critical. When the machine is down, you are losing money. Ensure the supplier has a strong local presence, qualified technicians, readily available spare parts, and offers comprehensive training for your operators.

- Pitfall 5: Ignoring Future Business Needs: Don't just buy for today. Where do you see your business in five years? Will you be working with new materials? Will you need to cut thicker sections? Will your volume increase to the point where automation becomes necessary? Choosing a machine with some degree of scalability or modularity can be a wise long-term strategy.

Conclusion and Selection Advice

The process of choosing the right sheet metal laser cutting machine is a journey of matching advanced technology to your specific application. The power to choose correctly lies in a thorough understanding of your own requirements.

How to Choose Based on Your Needs To make the best decision, ask yourself the following critical questions:

What are my primary materials and their maximum thickness?

Answer: If you exclusively cut metals, a fiber laser is the clear choice. If you need to cut a mix of metals and non-metals, a CO2 laser might be more versatile. Your maximum required thickness is the primary driver for determining the necessary laser power.

What level of precision and edge quality do I require?

Answer: For most applications, modern fiber lasers provide excellent precision. If you require mirror-finish edges on acrylics, a CO2 laser is superior. For weld-ready edges on metal, look for machines with advanced process controls and nitrogen fusion cutting capabilities.

What is my expected production volume and part complexity?

Answer: High-volume, relatively simple parts may benefit most from a high-speed, lower-power machine. Low-volume, highly complex parts require a machine with excellent accuracy and software. If 24/7 production is your goal, automation is not a luxury—it's a necessity.

What is my realistic budget, considering both initial cost and TCO?

Answer: Establish a budget that accounts for the machine, installation, training, software, and long-term operating costs. Compare quotes based on value and capability, not just the sticker price.

What are the capabilities and reputation of the supplier?

Answer: Investigate the supplier's service network, warranty, training programs, and customer testimonials. A strong partnership with your supplier is as important as the machine itself.

The Relationship Between Choice and Outcome Ultimately, the choice you make will have a direct and lasting impact on your business. A well-chosen machine becomes a profit center, enabling you to produce higher quality parts faster and at a lower cost. It opens doors to new customers and markets, fuels innovation in your product design, and provides a reliable foundation for growth. Conversely, a poor choice can become a constant source of frustration, with excessive downtime, high operating costs, and an inability to meet customer demands.

We encourage you to approach this decision with diligence and foresight. Engage with multiple vendors, ask for live demonstrations with your own parts and materials, and speak to existing users. By making a rational and well-informed decision, you are not just buying a piece of equipment; you are investing in the future efficiency, quality, and profitability of your entire operation.

Share This Post: